BE MORE EFFICIENT WITH YOUR AIR COMPRESSOR RUN TIME

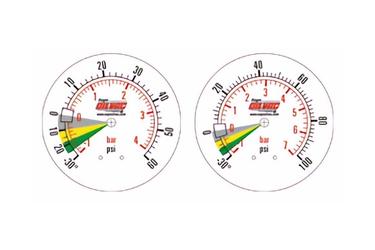

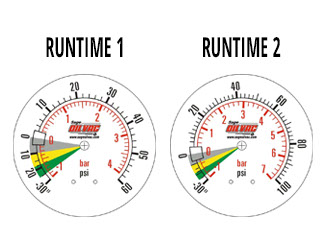

Being more efficient with your air compressor run time is important for several reasons. A favorite reason among operators is the cost savings it can bring to the table. Our competitors use conventional diaphragm pumps and air piston pumps in the tanks of their fluid exchange equipment. These require constant air volume from an air compressor to run. Sage Oil Vac systems conserve air by creating and maintaining vacuum pressure within the tanks. This is compared to conventional air pump systems which need to run air compressors 100% of the time.

When using Sage systems out on the jobsite, you can pressurize your tanks with the compressors you keep at the shop or on the jobsite with a gas-powered air compressor that can be added to your Sage model. Once you have necessary air pressure to dispense new oils, the compressor can be turned off. Sage professionals advise operators turn off machines once 20 inches of air pressure has been captured within the system. Using this advice ensures that the Sage systems reduce air compressor run time by up to 70% over conventional systems. This practice reduces the amount of wear and tear and our product operators often comment that the reduced noise of a Sage system prevents fatigue during the workday. For smaller and shorter shop applications, the Sage lube and fuel carts can be hooked into existing power and air compression systems to help power the task at hand.

Reduced air compressor run time + a standalone power lube truck = money in your pocket

Sage Oil Vac also offers lube truck options with standalone power for even more wear and tear savings. A standalone power lube truck uses a small diesel engine mounted on the body to run hydraulics for the fuel pump and the air compressor. That means fewer engine hours translates to reduced maintenance costs. Additionally, there are reduced fuel consumption costs from your truck and gas-powered air compressor and/or energy use costs if you’re using an electric air compressor. These added savings mean a standalone powered Sage Oil Vac lube truck could literally pay for itself.

Learn more

Want to know more about the benefits of Sage Oil Vac? Check out our full-line product brochure, lube truck brochure, LubeBuilder Brochure and product spec sheets.

Originally published September 30, 2016.