This March, Sage Oil Vac launched its first-ever Lube Skid Sweepstakes at the 2017 CONEXPO-CON/AGG Show. For four days, hopeful attendees entered our drawing to win the use of one of our covetted lube skids for an entire year. With hundreds of participants, the odds were favorable to many but fortunate to just one winner.

Meet the winner — Brandt Boone, Equipment Manager of Lester Contracting in Port Lavaca, Texas, entered the Sage Oil Vac booth just like countless others, but the luck of the draw put him a cut above the rest.

“I went to CONEXPO with some of my Lester Contracting counterparts,” Boone said. “I have been interested in the past year or so in getting the company a lube skid for our mechanics, so we were visiting as many people with skids as possible to see the things they had to offer.”

Lester Contracting has served the surrounding areas of South Texas as a civil contractor since 1959. Their primary services include dirt work and utilities (water and sewer).

“The Lester Contracting Vice President received an email that we had won and I was excited to try out the lube demo,” Boone recalled. “It will give us something to do our large-scale and smaller oil changes ourselves. At the moment we actually have to (hire out) to have some of our large-scale oil changes done.”

The Sage Oil Vac Lube Skid Sweepstakes offered its winner the chance to choose the lube skid that they will get to use for their demo period. With eight different models to choose from, the Lester Contracting group went through each model with a Sage representative to decide the right fit for their company.

“I set up a conference with two of our heavy machine mechanics and we talked about our large-scale oil changes and what we needed,” Boone said. “We talked about the types of oil we needed for each machine and we kind of came to a consensus of how we would want our skid to be built and what types of tanks.”

Lester Contracting decided to go with the 2H48-5 Heritage Lube skid with one 120-gallon used oil tank, four 60-gallon fresh oil tanks, five 50-foot reels and a grease package to be placed in an enclosed trailer. Each Heritage model is built to be robust and heavy duty with a smaller footprint — the perfect choice for trucks.

“Our Sage Oil Vac lube skid line is what really sets us apart from competitors within the industry, so we’re eager to hear feedback from the Lester Contracting company as the demo year progresses,” said Aaron Sage, Sage Oil Vac CEO.

Boone also anticipates the year to come with the Sage Heritage skid and is excited to bring boosted productivity and cost savings to the company.

“If we can cut costs and save money using a Sage skid that would be extremely beneficial to our company,” Boone said.

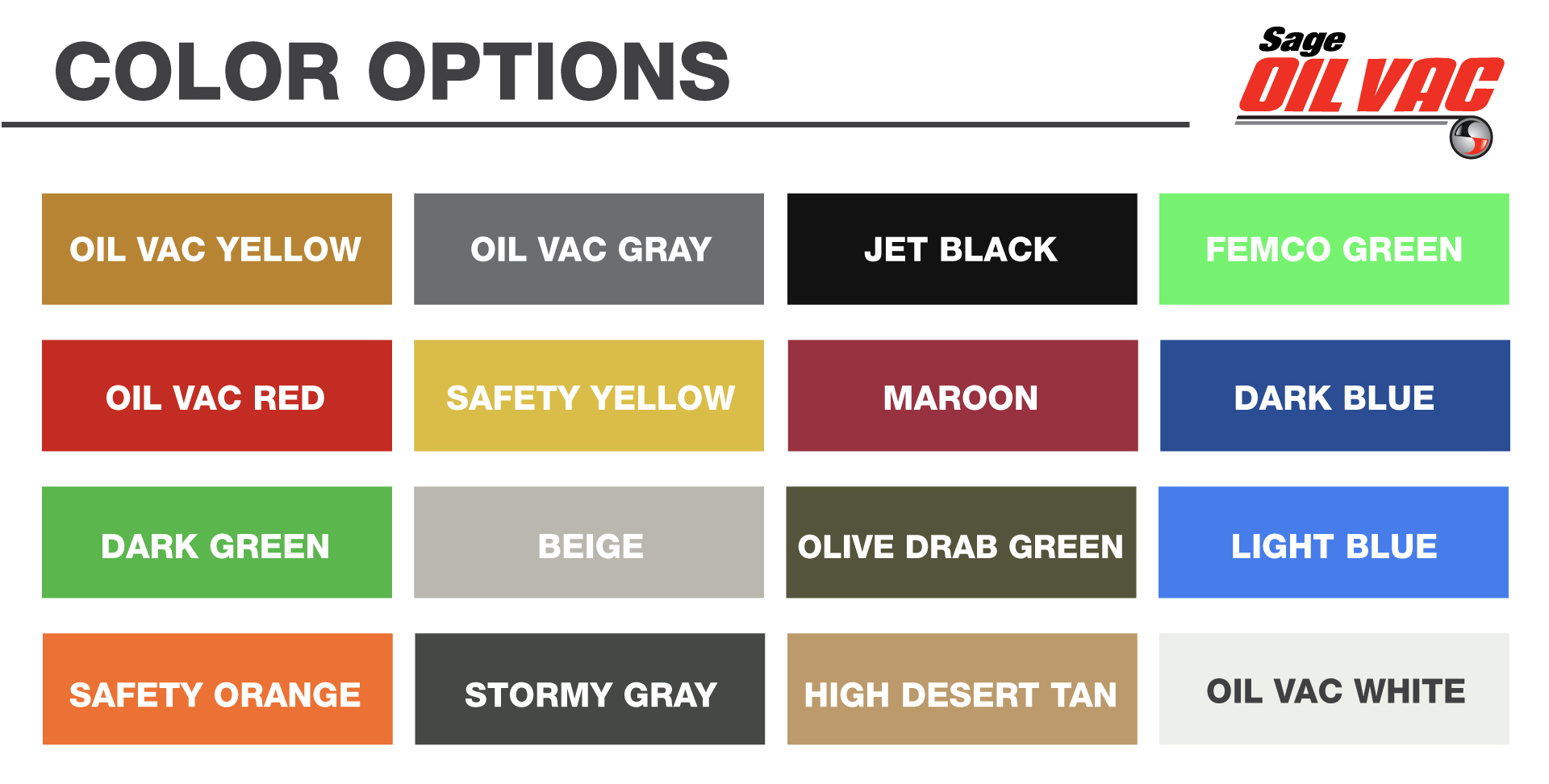

You asked and we listened. Sage Oil Vac is now prepared to bring your mobile lube equipment dreams full circle with our new custom color options. For years, the standard color for truck bodies has been oil vac white, and the standard colors for trailers, skids and carts have been oil vac yellow tanks with oil vac gray unit frames. But after seeing the increasing inquires for custom colors, Sage decided it was time to create more options. For an additional per unit upcharge, we now offer a select palette (see below) of new paint choices. Customers can also elect to provide their own color specifications outside of the color palette, but will be subject to an additional one-time color match fee.

Sage Oil Vac Paint Process

1.Verify paint selection with customer.

2.Pressure wash frames with a degreaser to remove mill oil and blast fabricated frames with Garnett, to prep to surface for paint.

3.Paint system using PPG Industrial Urethane DTM paint.

4.Touch up product as needed.

Please contact Sage Oil Vac for more specific paint information and custom pricing upcharges. View the color options here.

Every entrepreneur’s road to success is unique and one of a kind, Sage Oil Vac lives for the days when their equipment can help boost business. Eric Sanchez, owner and operator of EV Powerwash & Lube, LLC in Midland, Texas, says coming across Sage did just that.

Every entrepreneur’s road to success is unique and one of a kind, Sage Oil Vac lives for the days when their equipment can help boost business. Eric Sanchez, owner and operator of EV Powerwash & Lube, LLC in Midland, Texas, says coming across Sage did just that.

In 2013, Sanchez was a physical therapist by trade, but he just couldn’t pass up an opportunity to take advantage of the booming oil economy.

“I started with just a $400 powerwasher and a truck, and for a while I would just go around and wash oil transport vehicles,” Sanchez said. “Then in 2014, I started leasing an old gas station and I converted it into a lube shop where we did oil changes, safety inspections and powerwashes on just passenger vehicles.”

As his business clientele grew, Sanchez began to reach out to more commercial customers to see if they would be receptive to using him for their on-site personal maintenance (PM) needs.

“I started out doing personal maintenance for a couple customers that had transports and that is when I met Dwayne Green at Oil Patch Power and bought a Sage Oil Vac PM unit to continue doing that,” Sanchez said. “The big break was when I gained the business of ProPetro.”

ProPetro, a Midland, Texas-based oil field services company, provides hydraulic fracturing and other services to North American oil and gas companies.

“They let me start with their transport engine maintenance,” Sanchez recalled. “Once we built their confidence with that, they slowly started letting us work on their hydraulic pumps which require much larger engines with a lot more oil and filters. Now we’re doing maybe 60-70 percent of their equipment PM services.”

After Sanchez established ProPetro as a regular client, work requests from other companies started rolling in. This lead to a few more purchases from Green at Oil Patch Power and several new hires to his team.

“It’s been fast, it started as a leap of faith and it’s worked out,” Sanchez said. “I started with five employees and now I’m up to 30.”

EV Powerwash & Lube, LLC currently utilizes two Sage Oil Vac PM trailers and three lube skids. With the increasing jobsite no-spill regulations, Sanchez said the Sage equipment has really helped keep things clean.

“Everything we do has to be properly contained, properly vacuumed and disposed of, which is something we encounter with oil changes,” Sanchez explained. “Sage has made our job more efficient and more productive. It’s worked very well for us and the equipment is very well built. It’s definitely been a part of our success.”

Download and share this customer story.