Time is money on the jobsite. If you’re spending too much time using conventional means to change oil on the job, it’s likely costing you money, and certainly preventing your operation from working at its peak capacity.

When we talked to Michigan-based Caterpillar heavy equipment dealer, we learned just how much productivity is gained when using a Sage mobile lube or oil system verses a traditional pump system. The company frequently changes oil in power generators and beyond so when they heard about Sage Oil Vac they were ready to give it a try. Check out the comparison below to see the full scope of Michigan CAT’s potential time savings.

Before Sage Oil Vac

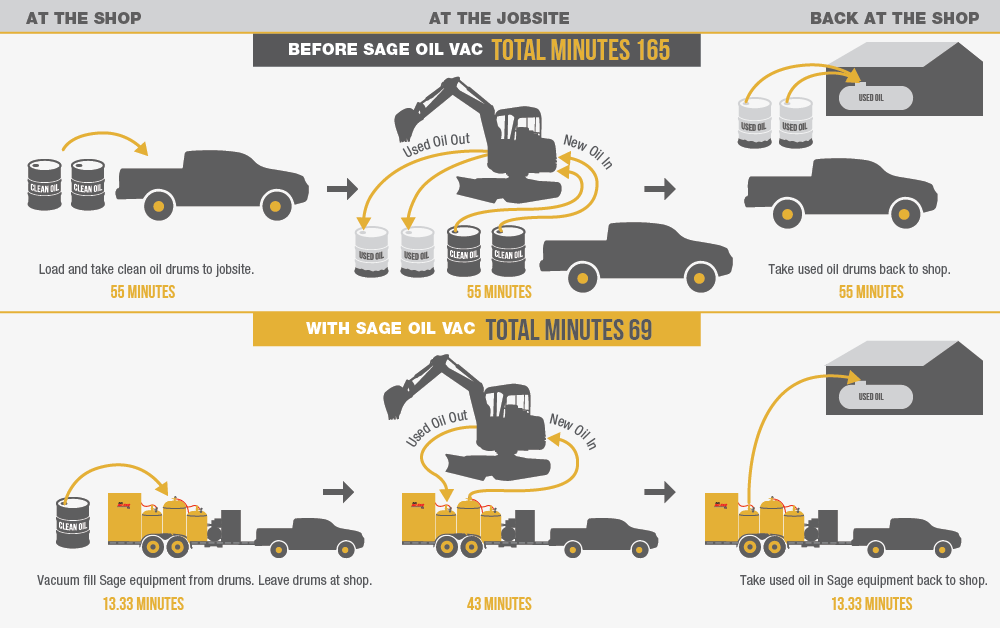

Michigan CAT services and maintains a group of power generators in the lower peninsula of Michigan, a job that requires the removal and replacement of 110 gallons of oil for each machine. Using conventional means — typically comprising delivering two 55-gallon barrels of oil to the jobsite, switching out oil manually and returning barrels of used oil to a central shop — Michigan CAT service technicians averaged almost three hours per oil change.

To break the time savings down further, let’s do some math. Michigan CAT started their oil exchange process by loading two 55-gallon drums of oil into their truck before driving to the generator. The generator, which holds 110 gallons of oil, takes 55 minutes to vacuum the used oil into two empty drums. Then it takes an additional 55 minutes to pump two drums of new oil into the generator. Once this is complete, the operator returns to the shop to dump the used oil into a used oil tank which takes yet another 55 minutes. All in all, the total oil change cycle lasts a total of 165 minutes.

Jobsite time savings with Sage Oil Vac

Using a Sage 1C5F-2100 preventative maintenance (PM) trailer cut that maintenance time drastically. What took Michigan CAT techs almost three hours took just a fraction of the time.

According to Michigan CAT, the time comparison when using a Sage system was felt right out of the gate. Before leaving the shop, it took 13 minutes to fill the 1C5F-2100 PM Trailer with two drums of fresh oil. Then it took about 13 minutes to vacuum the used oil from the generator, 30 minutes to refill it with fresh oil and another 13 minutes to discard the used oil when they returned to the shop.

In all, technicians can save an average of 96 minutes per oil change start to finish. In many cases, that’s enough time to conduct at least one more oil change per day, enabling operators to create new efficiencies, service more equipment and build new business growth opportunities.

“Saving this much time per day adds up to major savings for the operator,” said Sage CEO Aaron Sage. “In addition to our systems making it easier to maintain a clean jobsite, operators can simply get more work done and get more machinery serviced every day.”

See more details about how time can be saved. Find your nearest Sage dealer to make the change and get more from your time on the jobsite.