We can give away free Sage Oil Vac swag and talk up our amazing pump-free exchange systems until we’re blue in the face at the 2017 CONEXPO-CON/AGG show, but why just tell you about it when we can send you home with it? Yes, you read that right. We’re putting our equipment to the ultimate test — we’re giving away the use of a Sage lube skid for an entire year to one lucky winner.

“Our Sage Oil Vac lube skid line is what really sets us apart from competitors within the industry,” said CEO Aaron Sage. “It’s our flagship product and we’re market leaders in customizing skid packages.”

Right now, you’re probably saying something like: All right I’m in. How does the Sage Oil Vac Lube Skid Sweepstakes work? Easy. Just stop by Sage Oil Vac’s booth (S63129) at the 2017 CONEXPO-CON/AGG Show (March 7-11) or go to our online landing page: www.SageOilVac.com/CONEXPO2017 to read the official sweepstakes terms and conditions and submit your information to enter. The winner (who will be chosen at random) will then get to select the skid model they wish to use for a year.

“Anyone with heavy equipment that needs maintaining (so everyone) should enter this sweepstakes,” Aaron said. “If they win, they can pick their lube skid model and choose the unit that best fits their operation’s needs.”

With eight different models to choose from — Sage lube skids are often found in crane trucks, van bodies and mechanics’ trucks. Sage skids are great for servicing light towers, generators and trucking fleets with their smaller fluid capacities. These units are best suited to work vehicles with air compressors already mounted. Forklift pockets and mounting holes are standard in all skid models for easy transport. Our signature Sage Oil Vac pump-free design, creates a low maintenance skid with an estimated 10+ year product life.

“The best part of this product line is that it’s so versatile with all the different model sizes,” Aaron said. “The most popular model is a 2M46-3100 service skid which works well in the construction and ag industries as well as third party service companies who maintain fleets.”

With nothing to lose and everything to gain, Sage Oil Vac is encouraging everyone to enter online, even if they’re not attending the show.

“What we hear the most from our customers is that they love being able to end the day without having to change clothes — they usually end the day as clean as when they started,” Aaron said. “Couple that with faster fluid exchanges and low maintenance costs, and I think our product quality speaks for itself.”

Sage Oil Vac, a market leader in professional lube equipment, is excited to announce the launch of its next ‘big’ product innovation — the NextLube monitor system. While it might not be large in size, the all-new NextLube monitor system will bring huge improvements in terms of productivity and ease of use.

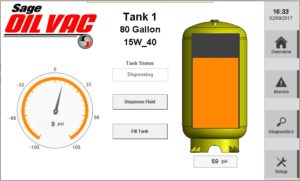

NextLube will allow operators to integrate data while incorporating automation and fluid control with Sage Oil Vac mobile lube equipment. Based on customer feedback, Sage is developing this system to allow for more operator control with a touch screen centralized control panel to take out the manual actuation of valves.

NextLube will allow operators to integrate data while incorporating automation and fluid control with Sage Oil Vac mobile lube equipment. Based on customer feedback, Sage is developing this system to allow for more operator control with a touch screen centralized control panel to take out the manual actuation of valves.

“Based on customer feedback, we developed NextLube to allow more operator control,” said Sage Oil Vac CEO, Aaron Sage. “NextLube will act as a centralized control panel, so operators can have automated fluid dispense capabilities and monitoring within Sage Oil Vac mobile lube equipment.”

NextLube also streamlines maintenance operations by providing real-time fluid levels, totalized quantities of oil dispensed, flow rates and oil temperatures, all while having the capability to tie into existing customer telematics operations. It will also streamline maintenance operations by creating the ability to label individual tanks for quick recognition and organization. With more information to be given to the operator, this product will simplify the job by reducing the learning curve for new operators.

The intuitive touch screen panel will bring a straightforward presentation of information to every job as an optional add-on to Sage Oil Vac equipment. NextLube will display the gallons within the tanks, instead of the percentage, making the process easier for the technician to determine the amount of oil available to complete an exchange. More safety features and logic will be built into the system.

“The overall digitization of what has previously been a manual process creates additional possibilities in future updates,” Aaron said. “This could include running the system from an app on a smartphone or tablet, or incorporating back-end costs and telematics to specific equipment. The sky is the limit.”

NextLube system among top construction innovations

Each year, Construction Equipment magazine recognizes the industry’s most innovative new products — as well as companies’ commitment to research and development critical to bringing them to market — in its Top 100 New Products Award program.

Each year, Construction Equipment magazine recognizes the industry’s most innovative new products — as well as companies’ commitment to research and development critical to bringing them to market — in its Top 100 New Products Award program.

After a lengthy review of the myriad products new to the construction equipment sector in the last year, the 2018 list includes a big innovation from Sage Oil Vac, the NextLube monitor system.

“We considered several hundred product introductions in the process that led us to [the NextLube monitor system],” said Construction Equipment editorial director Rod Sutton. “Our editors made these selections independently, drawing upon our own experience with equipment technology and the equipment marketplace.”

That spirit of innovation and continued work to improve upon the NextLube system in the future was also a key component of the Construction Equipment Top 100 New products of 2018 Awards program.

“These awards serve to emphasize innovations, highlighting manufacturers who are investing in research and development. Their investments pay off for equipment users in the form of greater productivity, efficiency and safety,” Sutton said. “They also ensure a competitive marketplace.”

Contact your local Sage Oil Vac dealer for more information.

The entrepreneurial spirit is as important to Sage Oil Vac as it is to one of its most successful dealers, Cobalt Truck Equipment.

Just two years after Gary Sage founded Sage Oil Vac in 1993, Dan Duncan, President and owner of Cobalt Truck Equipment, opened shop in Idaho. Today, both companies are thriving and working together to bring the best products to customers within the construction, utility and heavy equipment industries.

“Cobalt’s introduction to Sage Oil Vac started with our interest and the needs of our customers for servicing wind equipment,” said Cobalt Vice President of Sales and Marketing, Paul Bedke. “Once the relationship developed, we discovered Sage met even more of our customers’ needs outside of wind power.”

Cobalt Truck Equipment works from four locations across the U.S. to provide customers with quality mechanics trucks, lube trucks, utility bodies, platforms, vans and more.

“Cobalt customers that use Sage products have been very pleased with the performance and efficiency of the Sage design,” Bedke said. “One customer in particular has converted all of their truck specifications to include the Sage waste oil system.”

Sage has provided on-site training to all four Cobalt locations (Nampa, Idaho; Spokane, Washington; Las Vegas, Nevada; and San Antonio, Texas). In addition, Sage sales representatives have participated in multiple trade shows and events with the Cobalt sales team.

“The lube trailers are some of the more popular items for our sales reps,” Bedke said. “The trailers provide diversity with our customers and their service trucks without the large investment of a dedicated lube truck.”

Cobalt currently offers the entire Sage Oil Vac product line.

“Sage is a good company with a long history in the vacuum-operated lube equipment business,” Bedke said. “They are very responsive to customer demands and do their best to provide a solution to meet those needs.”

Download and share this customer story.

To rent or to buy? It’s a question that plagues everyone in their lifetime, but for those in the wind turbine servicing industry options have always been limited. That is, until Sage Oil Vac began its Gear Oil Exchange (GOEX) Rental Program in 2009.

“Sage Oil Vac started the GOEX Rental Program based on the demand within the industry and from customer requests,” said Midwest Territory Manager, Chance Castillo. “Some companies needed to provide oil changes but didn’t necessarily want to make the full investment of purchasing.”

Sage currently rents out 1E6M-4 and 1E6K-3 models (with plans to add a 1D6G-2 to the fleet in spring 2017). Each model utilizes two tanks for Sage’s unique pump-free oil exchange system which allows the end-user to dispense and drain oil faster with vacuum technology. The 1E6M-4 has an additional two tanks for full flush and rinse capabilities, while the 1E6K-3 has one additional tank for limited rinsing capabilities or to carry a hydraulic fluid.

“How do our customers decide on renting versus buying? Well that all depends on the wind farm,” Castillo explained. “With our GEOX, the time between maintenance periods can be extended to anywhere from two to five years. It often makes more sense to rent a unit for a couple of months, perform the oil changes, and not have to think about it for a few years.”

Sage Oil Vac completes a thorough cleaning and checklist program between renters – new filters are installed and tanks are purged.

“Renters enjoy this program because it saves them from the initial capital investment and the hassle of maintaining the unit during the unused periods,” Castillo said. “The only thing they need to worry about is having a truck big enough to run the system. A ¾-ton truck is the minimum weight needed, but a 1-ton pickup is preferred as they can weigh up to 12,000 lbs during operation.”

GOEX systems in the program can be shipped anywhere within the continental U.S. on behalf of the customer or they can be picked up and dropped off at Sage Oil Vac headquarters in Amarillo, Texas. Training can be completed a few different ways — via a YouTube tutorial, if the unit is picked up in person in Amarillo, or a technician can travel to a wind location for an additional expense.

“I would conservatively say our rental units have performed as many as 3,000 gearbox rinse and flush operations on wind turbines across North America in the last six to seven years,” Castillo said.

Contact Sage Oil Vac for more GOEX Rental Program information and pricing!