Our stance has never wavered: The Sage Oil Vac pump-free design is the foundation of a better fluid exchange system — a faster, safer and cleaner way to change oil and fluids on your jobsite.

There are, of course, some skeptics. Systems featuring air-operated diaphragm pumps (AODPs) and air piston pumps have provided a dependable means of changing oil and fluids for decades. Proponents of these systems question whether there is truly a performance advantage to a system that uses compressed air to build vacuum pressure that moves fluids to and from tanks.

The Advantage of a pump-free fluid exchange system

Our response: There is a HUGE advantage with the Sage Oil Vac pump-free design.

Of course, don’t just take our sales pitch as gospel. We put the two systems to the test. Sage Oil Vac versus the competition. Conventional pump-dependent systems pitted against our patented design. May the best fluid exchange system prevail.

This comparison took place in a controlled setting, therefore the results for either system may vary in real application based on weather conditions and other variables, like viscosity and temperature.

Challenge No. 1: Removing used oil

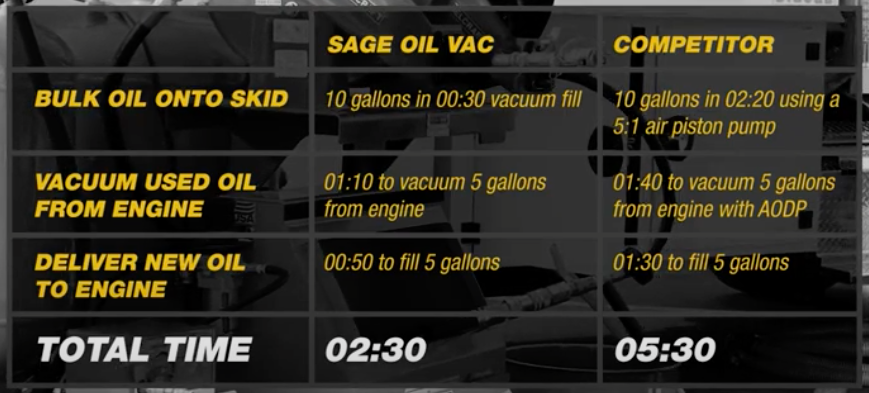

The first fluid exchange system showdown featured a Sage Oil Vac system and one using air-operated diaphragm pumps to remove five gallons of used oil.

-

The results

- Sage Oil Vac: 1 minute, 10 seconds

- Air-operated diaphragm pump system: 1 minute, 40 seconds

Challenge No. 2: Dispensing fresh oil

For the second showdown, we bulk-filled 10 gallons of oil into each skid (a Sage Oil Vac skid and one fluid exchange system using an air piston pump) and performed an oil change on an engine that holds five gallons of oil.

-

The results

- Sage Oil Vac: 30 seconds (approximately 20 gallons per minute)

- Air piston pump system: 2 minutes, 20 seconds (approximately 4.25 gallons per minute)

Conclusion

The results speak volumes. Whether you are removing used oil or fluids or bulk-filling fresh oil or fluids into your equipment, Sage Oil Vac pump-free fluid exchange systems are faster and more efficient. Plus, they provide a cleaner way to change fluids, greatly reducing the chances of spills or contamination.

See our pump-free fluid exchange system for yourself

Watch the Oil and Fluid Exchange System Showdown to see how our system prevailed over competitive models.

The latest adjustments to our onsite oil change equipment

In addition to new product development, evolving current Sage Oil Vac equipment designs is an important part of our business. No matter the product or the solution, components to our onsite oil change equipment can almost always be made better. We’re constantly testing new ways to do things, trying different building materials and seeking feedback from our customers on how we can improve. Check out a few of our latest innovative updates…

Redesigned Vac T component

The Vac T was created to have less wear parts on the top of the tank that might be susceptible to corrosion or leaking over time. The previous design had multiple pieces and fittings which increased the likelihood of premature wear over time which could eventually cause leakage. The updated Vac-T piece is a custom pre-cast resolving those issues. The Vac T also reduces the height of Sage Oil Vac LubeBuilder tanks by a couple of inches, allowing it to fit more easily in tight Lubebuilder upfit configurations. Just one way, Sage Oil Vac looks to create custom solutions to increase the life of our onsite oil change equipment.

Relocated bulk fill stations on all truck models

Previously, all bulk fill stations were housed within the rear reel cabinets of any Sage Oil Vac truck model. While this design had good intentions, the location required longer hose lines to be able to extend their reach and get the fluid to the tanks. It also created a bit of chaos and the potential for added mess when it came time to tackle replacement parts or address other issues. Moving the bulk fill station to the truck side body cabinets, brings lines closer to the tanks and prevents hose entanglement for and easier, cleaner and faster hook-up and fill.

>> View our Sage Oil Vac Lube Truck models.

Enhanced Used Filter Receptacle™ design

For those unfamiliar with our unique Used Filter Receptacle (UFR) accessory, this piece of Sage Oil Vac onsite oil change equipment provides a secure and leak-proof holding tank for used filters. The UFR is available in several designs based on its intended mount location and it connects to a used fluid tank so users can easily vacuum oil that may drain from the discarded filters. Cutouts were added to the side of the UFRs, within reel cabinets, in our latest design update to help nozzles and meters locked during transportation and catch any remaining drips.

>> Find out which UFR configuration would work best for your setup.

Customer feedback is always welcome

Have an idea, suggestion or request to make Sage Oil Vac onsite oil change equipment even better? We want to hear it! Get a hold of our team.

Let’s talk about some common misunderstandings and concerns we often hear about Sage Oil Vac fluid exchange systems. That’s right, we’re putting ourselves in the hot seat to clear up the most popular misconceptions about our product lines — after all, we’re the ones who know it best.

How Sage Oil Vac systems work

(Feel free to skip this section if you’re familiar with our brand — or watch our video.)

Pump-based oil extraction equipment has been the industry standard for decades, but that’s only because it’s what people have always known, not because it’s the greatest way to achieve the end results. Pump-based equipment needs constant, high-volume compressed air while you’re operating, Sage Oil Vac systems do not.

Sage fluid exchange systems use a patented pump-free design, allowing the end-user to dispense and drain fluids faster using cutting-edge vacuum technology. Compressed air builds vacuum and or pressure to move fluids to and from tanks. Our system goes against the grain of the traditional pump-based technology, offering customers who make the switch a cleaner, more energy-efficient oil change on the job.

Setting the record straight

Misconceptions No. 1 and No. 2:

Sage Oil Vac systems require more air compressor run time and are louder than pump-based oil extraction equipment.

Let’s tackle these two together. Sage Oil Vac systems actually use less compressor run time than pump-based equipment. Our systems conserve air by creating and maintaining vacuum pressure within the tanks. When using Sage Oil Vac systems out on the jobsite, you can either pressurize your tanks in the shop with compressors before you leave or on the jobsite with a gas or diesel powered air compressor that can be added to your Sage model. This is compared to conventional air pump systems which need to run air compressors 100% of the time.

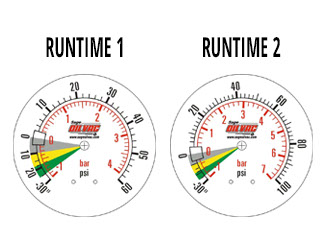

Once you have the necessary air pressure to dispense new oils or drain used oils, the compressor can be turned off. Sage Oil Vac professionals advise operators to turn off machines once 20 inches (50.8 cm) of vacuum has been captured in the waste tank and 60-80 psi in the fresh oil tank. Using this advice ensures that Sage Oil Vac systems reduce air compressor run time by up to 70% over conventional pump-based equipment, and therefore reduce overall air usage.

This practice minimizes the amount of wear and tear on equipment and significantly lessens onsite noise and — in some cases — added emissions. Our product operators often comment they enjoy the quietness of their Sage Oil Vac system. Without needing a compressor to run the entire time or experiencing the noises from diaphragm/piston pumps, their workday fatigue improves.

Misconception No. 3:

Sage Oil Vac systems require and use more pressure than pump-based oil extraction equipment.

Pump-based equipment uses waves of pressure to extract/insert oil versus the Sage Oil Vac system, which uses constant vacuum pressure to pull/push oil. This equates to less fluid pressure per square inch (psi) usage. A diaphragm pump system with one piston pump generates 500 psi in pulses. Our system uses 60-80 psi of steady pressure. Reduced psi requirements almost always correlate with reduced risks for machine malfunction.

Misconception No. 4:

Sage Oil Vac systems weigh more than a conventional pump system.

Sage Oil Vac systems actually weigh less, as they don’t have the weight of a pump added to each tank. The lighter weight of Sage Oil Vac systems makes it easier for our engineers to create a non-CDL truck option to meet increasing industry demand for more lube bodies and service truck options that do not require a CDL.

How did we do? Do you have more questions? Contact the Sage Oil Vac team to learn more.

As one of the largest and oldest Mack and Volvo truck certified Uptime Centers and dealerships in the U.S., family-owned Bruckner’s Truck Sales is always looking for ways to be more efficient. Across 32 locations in seven states, Bruckner’s services trucks, trailers, and sometimes equipment with parts not original to the manufacturer. To keep equipment on the road and customers happy, it’s important for Bruckner’s to not only have an inventory of parts but the right tools for efficient service.

LEAVING THE OLD-FASHIONED WAY BEHIND

One specific maintenance area that had increasingly become a headache for their service team was transferring coolant lines off of the transmission without contamination, especially when working on equipment that has parts not original to the manufacturer. While Mack and Volvo use a quick-connect fitting hose for a more seamless transfer, other OEMs use a butterfly valve, which can clog more easily.

“Butterfly valves tend to clog up during coolant exchanges, so when we used to encounter one, we would have to do the service the old-fashioned way,” said Ryan Moore, service manager of Bruckner’s Fort Worth, Texas, location.

The old-fashioned way called for coolant to be drained into a pan, which often also caught debris and made the coolant unusable after engine maintenance was complete. That meant replacing it with new coolant even if it still had plenty of life left — and the stuff is not cheap. Standard silicate antifreeze typically lasts around two years or 30,000 miles while extended drain coolants perform up to five years or 100,000 miles.

After performing the service, Moore said they would then refill with new antifreeze from the top. As most operators know, adding in coolant from the top tends to leave a lot of air in the line. To fix this, service techs have to start the truck, run it for a minute or two, shut it down, open the cap and release the air, then fill the system back up with more coolant. Sometimes this process needs to be repeated.

According to Moore, this whole rigmarole can add an extra 15 minutes or more to service times. With 32 Bruckner’s locations across seven states, that can add up to be a lot of time wasted, not to mention extra costs passed on to the customer for new coolant.

THE SAGE OIL VAC SOLUTION

Ultimately, Moore wanted to find some way to make the coolant exchange process quicker, and he found it with a Sage Oil Vac 3011-1200 recycler cart. Gaining the ability to cleanly preserve fluid has been a big added bonus for cost savings.

“The 3011-1200 recycler cart is handy because we can do these complex coolant exchanges much faster than the old-fashioned way,” Moore said. “With this cart we can load the coolant from the bottom, ensuring most of the air is pushed out to the top from the beginning.”

out to the top from the beginning.”

The coolant recovery unit’s enclosed system uses vacuum pressure to remove fluid without the danger of contamination. The wheeled unit features a 20-gallon tank for ample storage and a 15-foot, ½-inch (4.5-m, 1.27-cm) hose. This enables technicians to easily reach antifreeze tanks.

“We tried some other brands but had issues with them — one small piece of debris would usually mess things up,” Moore said. “The 3011-1200 cart has a lot less room for error and a better valve assembly.”

All Sage Oil Vac lube carts come equipped with patented Sage Oil Vac vacuum process and fluid level sight plugs with added precision. A CV-20 vacuum generator provides power along with a required additional air source.

“Our service technicians are much happier because they can get the job done faster — if each one could have a recycler cart in their own bay they would,” Moore said.

The Fort Worth Bruckner’s team has four 3011-1200 recycler carts, but they’re looking to order more. Moore said he would describe his relationship with the Sage Oil Vac team as “streamlined.”

“I can send an email and get another cart, or any products basically, at the snap of a finger,” Moore said. “It’s no hassle. They know what we need, and then we get it.”

Find out more about Sage Oil Vac lube carts and contact the Sage Oil Vac team with any questions.

Operating an equipment rental business can create unique, specific maintenance challenges. The team at Crown Rental in Burnsville, Minnesota, has over the years learned how to overcome those challenges in serving its consumer and small contractor customer base in Dakota County, Minnesota, and the South Metro area of the Twin Cities. A year after adding a Sage Oil Vac lube cart system, the Crown Rental team is taking stock of how it’s changed their machinery maintenance operations for the better.

The idea of delivering a new level of service was in mind when Crown Rental maintenance techs and leadership saw a Sage Oil Vac 3011-1100 evacuation lube cart and the functionality the small but mighty tool could bring to their maintenance needs. So, when a stroke of luck provided them the opportunity to try it out, they jumped at the chance to put it to work. In doing so, they discovered the benefits of the pump-free Sage Oil Vac compressed air system, not just taking care of routine machinery engine maintenance, but also to manage some of the maintenance tasks that come with renting excavation and power equipment in a largely suburban marketplace.

“We rent a high volume of equipment to small contractors, homeowners and municipalities. Our customers may rent equipment for one day or one month, and 95% of the time, we conduct the service once the rental is completed,” said Crown Rental Service Technician Jarrod Heath. “We rent and maintain air compressors, drivable boom lifts, wood chippers, excavators, bulldozers, light towers and small generators.”

Luck of the draw

With expanding ways to serve that equipment rental business customer base in mind, Crown Rental Owner Doug Haas attended the 2020 American Rental Association (ARA) convention and trade show in Orlando, Florida, where he connected with the Sage Oil Vac team. Haas was the winner of a Sage 3011-1100 evacuation lube cart giveaway at the Sage trade show booth, and that tool introduced Haas and his team to a new way to change oil in machinery. Haas eventually also purchased a Filter Stinger™ and Dipstick Tube Evacuation kit for the cart. Now a year later, the system has altogether changed how Crown Rental maintenance team members do their jobs.

With expanding ways to serve that equipment rental business customer base in mind, Crown Rental Owner Doug Haas attended the 2020 American Rental Association (ARA) convention and trade show in Orlando, Florida, where he connected with the Sage Oil Vac team. Haas was the winner of a Sage 3011-1100 evacuation lube cart giveaway at the Sage trade show booth, and that tool introduced Haas and his team to a new way to change oil in machinery. Haas eventually also purchased a Filter Stinger™ and Dipstick Tube Evacuation kit for the cart. Now a year later, the system has altogether changed how Crown Rental maintenance team members do their jobs.

“Before Sage, we hadn’t really explored new options for lubricating equipment. We were just pulling drain plugs and draining into pans, then into a bulk waste tank. The main headache we had with changing oil on smaller equipment was caused by the location of drain plugs and the process of draining oil. We used to have to take multiple drain pans with us on our service trucks, and they would always overfill and spill oil everywhere,” Heath said. “With the Sage unit, our mobile service techs can vacuum out the oil pans while we’re draining the oil out of the machinery. It changes the job completely and eliminates so much of the mess we faced before.”

The lube cart solution to routine and unique problems

And that’s just with routine maintenance; Heath said his team’s been able to use the Sage lube cart to manage problems that would otherwise be much more costly to solve.

“The lube cart was a huge help when we had an issue with a customer mistakenly filling a diesel engine with gasoline. We were able to vacuum and evacuate the gasoline from the entire diesel system,” Heath added. “We also used it once when a customer mistakenly added diesel fuel to a hydraulic tank. Those are headaches that can become bigger and costly issues, but they didn’t because we had the Sage system. It saved us a lot of time and we were able to get equipment back up and running and on to the next customer.”

An easy transition for service teams

Though the transition to the Sage Oil Vac system was a departure from normal operations for the Crown Rental equipment rental business maintenance team, Heath said it was an easy one. While he did have initial questions, his Sage Oil Vac rep was quick to find answers, so he was able to easily integrate it into his operations. Now a year later, he said it’s helped open his eyes to how tools like his Sage lube cart can help streamline once-cumbersome, messy and time-consuming jobs like changing machinery oil.

“Our relationship with the Sage Oil Vac team has been awesome. We’ve had no problems with the cart from an operational standpoint,” Heath said. “Whenever we’ve had questions or have needed additional parts, everything always happens in a timely manner. That helps us take good care of our machinery, keep it rented and keep our customers happy.”

If you’re thinking about ways to streamline your own equipment maintenance, contact a Sage Oil Vac dealer to learn more and put a system to work in your business.

Being equipped with the precise tools to conduct the unique equipment maintenance your customers demand is crucial for minimizing work stoppages and maximizing productivity. The proper system also provides your team with more than just what they need to perform equipment maintenance on the jobsite; it also helps keep them engaged and performing optimally.

And with the Sage Oil Vac LubeBuilder™ system, that’s exactly what you get.

WHAT IS THE LUBEBUILDER SYSTEM?

The Sage Oil Vac LubeBuilder system is a customizable, scalable and versatile collection of components that can be assembled into exactly the system you need. In all, there are more than 300 different configuration possibilities, with tank options ranging from 10 to 600 gallons, all oriented to fit your specific truck bed or other maintenance vehicle.

“This system isn’t just great for organization. A few common situations we see are when a pre-built lube skid’s footprint doesn’t fit, a customer can’t afford to get another dedicated truck or a lube trailer doesn’t work with the jobsite parameters they frequently visit,” said Sage Oil Vac CEO Aaron Sage. “Whatever the reason, a LubeBuilder system provides equipment maintenance operators with the lube exchange essentials to fit their exact set-up at a fraction of the cost.”

No one knows your jobsite needs better than you, and with a LubeBuilder system, you get the tools to tackle just that, plus all the benefits of the patented Sage Oil Vac no-pump vacuum technology and other innovations unique to the platform. Each LubeBuilder is a specific, unique solution to problems operators now no longer have to face when it comes to equipment maintenance.

WHICH SYSTEM RIGHT FOR ME?

| Do you want customization? | Regular lube skids have limited customization. Sage (and competitors) have several lube skid models and dimensions available, but these products are harder to customize. | The sky is the limit with a LubeBuilder system. You decide every element involved, from tanks and reels to the overall layout preferences. |

| Do you need to be able to move your system? | Easy – all you need is a forklift. | Transfer options are limited. Once a LubeBuilder kit is installed, it is likely staying with the vehicle. |

| Does the footprint matter? | Most lube skids are bolted within an unchanging static frame (e.g., 4 ft. x 6 ft.). | With LubeBuilder’s customizable footprint, the components of the uplift can be placed throughout the platform in ideal positions. Put tanks in one corner of the truck, and the reels and control panels at ground level off the side of a truck, for example, for easy access. It’s all up to you. |

| Do you need a shorter load time? | Regular lube skids require component assembly and welding, increasing the lead time by several weeks. | Because the system does not come pre-assembled, getting you the components, parts and tools shortens the lead time. Estimated 2-4 weeks for arrival after order design and completion. |

THE PROCESS

We’re often asked, ‘LubeBuilder systems are completely customized for each operation; that must mean it takes longer to get my system delivered and up and running, right?’ The process is actually quite efficient. Each system isn’t pre-assembled, meaning there’s typically just a two- to four-week turnaround time for design, manufacturing and delivery.

Michael Llewellyn, Shop Manager at Florida-based Johnson-Davis, Inc., was impressed with the overall process for his custom system. “The process was easy. I gave the Sage dealer our tank sizes and what we wanted, and they took it from there.”

Sage LubeBuilder systems will arrive complete with the tools, instructions and hardware to get it installed in your vehicle, plus one-on-one access to a Sage Oil Vac specialist who can walk you through the process quickly and efficiently.

Homer Gonzales, Field Technician at Ditch Witch Sales of Michigan, echoed the simplicity of the process and support from the Sage Oil Vac team, from start to finish. “Sage Oil Vac provided easy-to-use instructions and diagrams for installing the system in the back of my truck. The whole process took about eight hours and was pretty easy. I probably could’ve wrapped it up faster, but I’m pretty particular about my truck so I took a bit longer.”

PUTTING LUBEBUILDER TO WORK

On any given day, Louisiana-based Beard Construction is running more than 250 pieces of machinery across 12-15 commercial or industrial excavation jobsites. To meet the unique needs of their jobsites, Equipment Manager Lee Morrison knew they needed a customized, highly-reliable system to get maintenance done efficiently.

“I wanted a unit designed for specific applications that only had what we needed on it and nothing else,” Morrison said. “We knew the dimensions and that we needed full containment, and we got together and sketched out some drawings and came up with what would work best. With a lot of companies, you’re at their mercy, they have what they have and if you want it customized, you have to do it at your own shop. With this Sage system, we worked together and came up with the exact rig we needed.”

See more on how Beard Construction uses Sage Oil Vac LubeBuilder systems.

NOW IS THE TIME TO BUILD YOUR CUSTOM SYSTEM

“The sky’s the limit with these LubeBuilder systems,” Sage said. “You pick out every component and how it’s laid out. And our team will be there to walk you through installation so you’re spending less time in the shop and more time on the jobsite taking care of your customers and generating revenue.”

Are you ready to add a LubeBuilder to your operation? See the full specs of the systems and if you’re ready to go, contact us to zero in on your needs and how we can design the perfect system for your business.

Every member of the Sage Oil Vac dealer network shares their customers’ commitment to doing the job right. Throughout the company’s history, our dealers approach customer relationships with passion and dedication that help them go above and beyond the call of duty in sales, marketing, product knowledge and promotional activities that are all essential to year-over-year growth.

This year, we’re honoring our dealers who went even further to take care of their customers — an especially tall task in a year shaped by a once-in-a-generation pandemic — with the 2020 Sage Oil Vac Dealer Awards. These awards recognize the commitment of our dealer network in a year that posed unique challenges to everyone in our industry. See past dealer award winners.

“Our customers faced some unique challenges in 2020, and the award winners exemplify the dedication that is such a common thread among all Sage Oil Vac dealers,” said Sage Oil Vac CEO Aaron Sage. “The 2020 winners were integral to not just our company, but also the continued success of those they serve in some essential U.S. industries. We’re proud to call them members of the Sage Oil Vac family.”

Platinum Dealer Award: Oil Patch Power

Sage Oil Vac systems are in high demand in the Permian Basin oil fields around Odessa, Texas, where Dwayne and Goldie Green own and operate Oil Patch Power. The Green’s have long been a leading Sage Oil Vac partner, and have helped refine our product line to better serve oil field service contractors in their region, offering lube trucks, skids, trailers, carts, accessories and full LubeBuilderTM systems. Dwayne is one of the nation’s leaders in skid and lube sales and Goldie is the brains behind the operation that keeps everything running smoothly!

Since the Green’s are a big name in their area’s oilfield equipment service and maintenance sector, they’ve been integral to our advertising and getting our name out in West Texas, as well as demonstrating the benefits of our systems for their customers. We’re lucky to have the Green’s and Oil Patch Power as part of the team.

Gold Dealer Award: ACME Truck Body

ACME Truck Body is a member of the Sage Oil Vac dealer network and a leading provider of construction equipment and generator maintenance around Vero Beach, Florida. Company President Mark Steinberg has come to depend on Sage Oil Vac lube trucks and LubeBuilder systems to help his company’s customers get their jobs done, and in the process has become one of the area’s leading Sage sales and service providers. Steinberg and his team have singlehandedly helped grow the Sage customer base in the Florida construction equipment maintenance market.

Silver Dealer Award: Perfection Truck Equipment

Oklahoma City, Oklahoma-based Perfection Truck Equipment has come a long way in its 70-plus years of business. Today, the company that started with five truck lines now supports more than 120 truck lines and 100 lines of truck- and trailer-mounted service and maintenance equipment for the oil, gas and construction industries. And Sage Oil Vac LubeBuilder systems and lube trucks have become integral to the service the Perfection Truck Equipment team provides both its new and long-time customers in a major geography for Sage Oil Vac.

Looking ahead, Sage said he hopes to strengthen working relationships with members of his dealer network who can continue to deliver industry-leading mobile lubrication and equipment maintenance to key industries like oil and gas production.

“Our 2020 award winners embody what we value and what we know our customer’s value, and that’s an ethic of hard work and service to men and women focused on getting the job done right,” Sage added.

Contact your nearest dealer to learn more about the full range of Sage Oil Vac products.

Being more efficient with your air compressor run time is important for several reasons. A favorite reason among operators is the cost savings it can bring to the table. Our competitors use conventional diaphragm pumps and air piston pumps in the tanks of their fluid exchange equipment. These require constant air volume from an air compressor to run. Sage Oil Vac systems conserve air by creating and maintaining vacuum pressure within the tanks. This is compared to conventional air pump systems which need to run air compressors 100% of the time.

When using Sage systems out on the jobsite, you can pressurize your tanks with the compressors you keep at the shop or on the jobsite with a gas-powered air compressor that can be added to your Sage model. Once you have necessary air pressure to dispense new oils, the compressor can be turned off. Sage professionals advise operators turn off machines once 20 inches of air pressure has been captured within the system. Using this advice ensures that the Sage systems reduce air compressor run time by up to 70% over conventional systems. This practice reduces the amount of wear and tear and our product operators often comment that the reduced noise of a Sage system prevents fatigue during the workday. For smaller and shorter shop applications, the Sage lube and fuel carts can be hooked into existing power and air compression systems to help power the task at hand.

Reduced air compressor run time + a standalone power lube truck = money in your pocket

Sage Oil Vac also offers lube truck options with standalone power for even more wear and tear savings. A standalone power lube truck uses a small diesel engine mounted on the body to run hydraulics for the fuel pump and the air compressor. That means fewer engine hours translates to reduced maintenance costs. Additionally, there are reduced fuel consumption costs from your truck and gas-powered air compressor and/or energy use costs if you’re using an electric air compressor. These added savings mean a standalone powered Sage Oil Vac lube truck could literally pay for itself.

Learn more

Want to know more about the benefits of Sage Oil Vac? Check out our lube truck brochure, LubeBuilder Brochure and product spec sheets.

Originally published September 30, 2016.

Changing irrigation engine oil can become a cacophony of empty five-gallon buckets rolling around the bed of a pickup. The remaining dregs of some of those containers creating an oil slick covering just about everything in reach. Combined with the heat, the odor of burned or used oil, and the dirty or muddy conditions common around most irrigation engines, and it’s a scenario familiar to just about everyone familiar with a dirty jobsite oil change— and one that few enjoy.

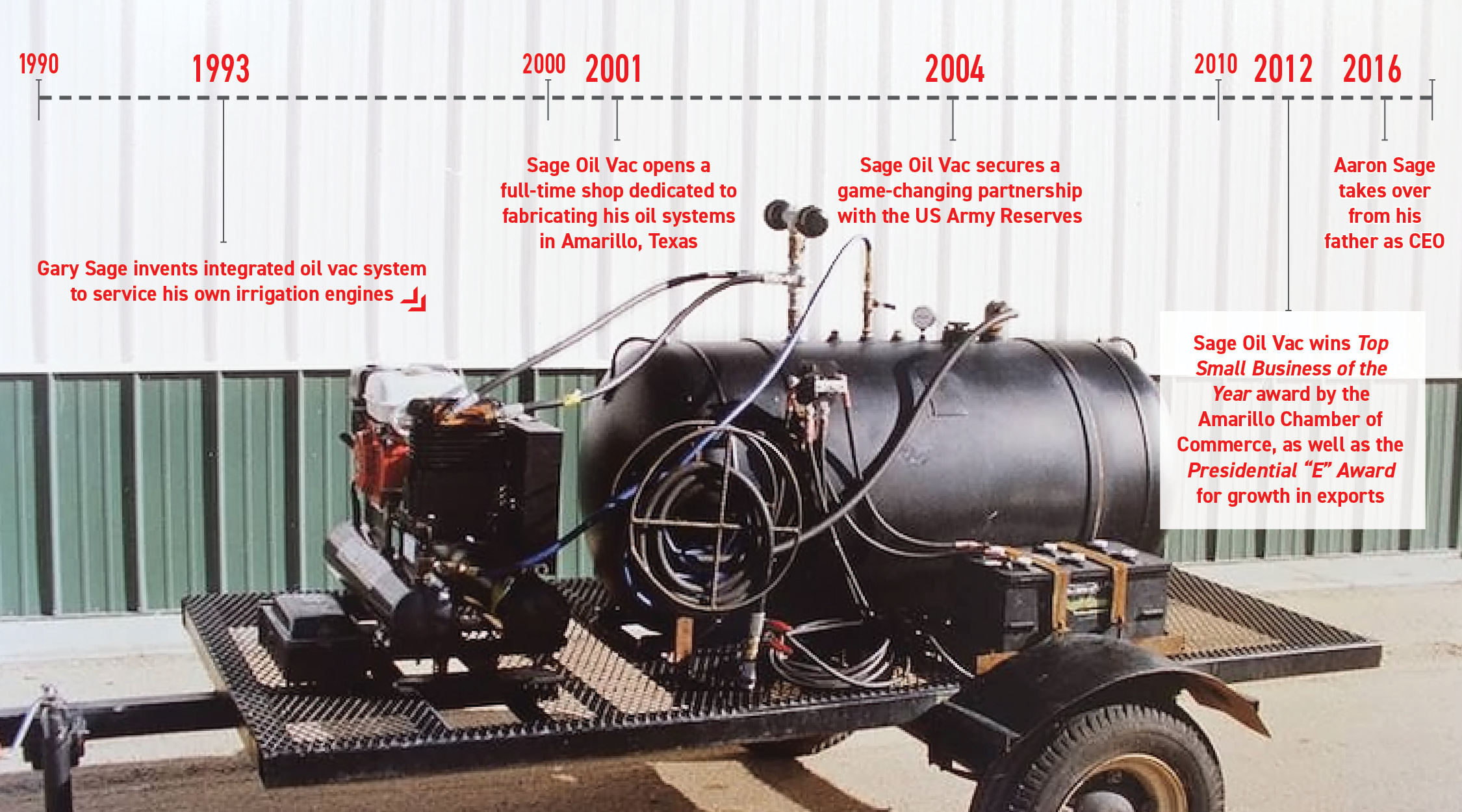

In 1993, that exact scenario had become reality for Gary Sage, and he was looking for a change. The inventor integrated the oil vac system he invented in servicing his own irrigation engines. The result: not a single drop of oil spilled on himself, his equipment, his machinery or the ground.

A range of jobsite oil change options

Now almost three decades later, Gary’s invention has become the foundation for Sage Oil Vac. This company is committed to efficiency and environmental sustainability on jobsites. Jobs range from irrigation and wind turbines to heavy excavation in the United States and around the world. Currently, Sage Oil Vac offerings include lube trucks, fuel and lube trailers, lube skids, lube carts, and a LubeBuilder™ system that can be customized to fit any vehicle and operation size.

All Sage Oil Vac oil exchange systems feature a pump-free design. It uses vacuum pressure technology and compressed air to exchange fluid at up to 15 gallons per minute, speeding up the process of a jobsite oil change. In addition to improving cleanliness and efficiency, Sage Oil Vac systems eliminates maintenance issues more common with pump-driven systems.

A decade of expansion

Eight years after his original system sparked the ambition to create Sage Oil Vac, Gary opened a full-time shop. The shop was dedicated to fabricating the systems in Amarillo, Texas, in 2001. In the decade that followed, he expanded the company by diversifying Sage Oil Vac systems. They started to outfit service technicians maintaining heavy equipment, generators, rental fleets, and oil and gas field machinery performing jobsite oil changes around the region. In 2004, the company created a partnership to custom-build oil vac systems for the U.S. Army Reserves.

After opening a new 24,000-square-foot facility to accommodate the growth that partnership created, Sage Oil Vac’s diversification continued with the 2007 development of the Gear Oil Exchange (GOEX) system for changing oil and servicing wind turbines. The GOEX system is available in a variety of platforms. This includes skids, open trailers, enclosed trailers, and trucks or offshore containers. It also includes an on-board filtration system that reduces wear particles on wind turbine gearboxes. This system significantly increases component and gearbox life spans.

The resulting niche market created by the development of the GOEX system took Sage systems to overseas customers when it gained distributors in Europe and Australia. In 2012, the company’s decade of evolution netted it the Top Small Business of the Year award by the Amarillo Chamber of Commerce, as well as the President’s “E” Award for Exports.

The next generation of leadership

Four years later, Gary Sage retired as Sage Oil Vac CEO, paving the way for son Aaron to take the company’s reins. Since becoming CEO in 2016, Aaron has continued to grow the family business. It now has a dealer network of more than 30 locations around the U.S. Though the company has evolved a great deal since its inception, the primary focus of Sage Oil Vac has not changed.

“We’re just as committed to bringing efficiency and environmental responsibility to consumers through the use of our mobile lube equipment as we were in 1993,” Aaron said. “Those who choose to ‘change with Sage’ do so because of the guaranteed quality equipment and unbeatable customer service.”

Learn more about how you can grow your business and make jobsite oil changes more efficient with the right Sage Oil Vac system.

When the COVID-19 pandemic threw the brakes on different parts of the global economy, some industries were brought to a crawl. For others — like some sectors of the construction business — it was a busy time in which general contractors around the U.S. continued to contribute to essential services and infrastructure work.

But for others idled by the virus, it’s created the time and the opportunity to focus on equipment maintenance as a way to both keep the workforce engaged and prepare for when more “normal,” busy operations resumed. In either case, Sage Oil Vac has had a role in the economy’s continued rebound from COVID-19.

“COVID-19 created all sorts of new challenges for our customers, and it took a toll on a lot of the men and women we work with every day,” said Sage Oil Vac CEO Aaron Sage. “Whether it’s been through mobilizing more service capabilities to bring more maintenance to your jobsite or ramping up maintenance operations to be ready when things return, we’ve worked to help keep our customers doing what they do best, making sure equipment that is in the field and on the job is well-maintained and performing at its peak potential.”

Sustaining essential work

In the wake of COVID-19, transportation fleet service and maintenance company operators and contractors working on essential infrastructure projects and jobsites were enabled to continue despite safeguards put into place to limit personal contact and the virus’ spread. Contractors and workers faced social distancing requirements and other recommendations to slow the virus. Often, that created challenges in how service and maintenance was performed. Mobile on-site maintenance was one way contractors not only continued operating on the jobsite, but did so while abiding by social distancing requirements.

“It’s impossible in a lot of cases to take something like an excavator off the jobsite or a truck off the road for maintenance when the service shop was closed or limited in appointments for social distancing,” Sage said. “Our mobile systems helped take oil changes to the jobsite. It helped operators keep trucks and machines running and minimized disruptions, and it also helped better maintain social distancing.”

Getting better for the future

For contractors and fleet managers who weren’t working on essential infrastructure projects, the pandemic created a slower pattern and downtime. Temporary lapses created time windows many — including rental store owners — used to service their equipment fleets, examining equipment maintenance strategies and making changes to improve their overall jobsite productivity. Though the integration of a Sage Oil Vac system can normally be a key component of a company’s growth strategy, the same tactic can help contractors and managers add value to otherwise lost time in the work stoppages.

“The COVID-19 interruption enabled many contractors fleet managers to make changes and integrate equipment that can make them more efficient in the future,” Sage said. “One of those adjustments is adding a Sage Oil Vac mobile system that best enables contractors to do their job based on the specific working conditions they are facing.”

Available in truck or trailer-mounted units, on skids or shop carts, Sage Oil Vac mobile systems are available in a range of sizes and configurations to meet the mobile oil change requirements of any contractor or rental store manager. You can even custom-build a system that meets your needs and fits within an existing footprint of a truck bed or sprinter van with our LubeBuilder™ system offering.

Find out which Sage Oil Vac system is best for your operation here.