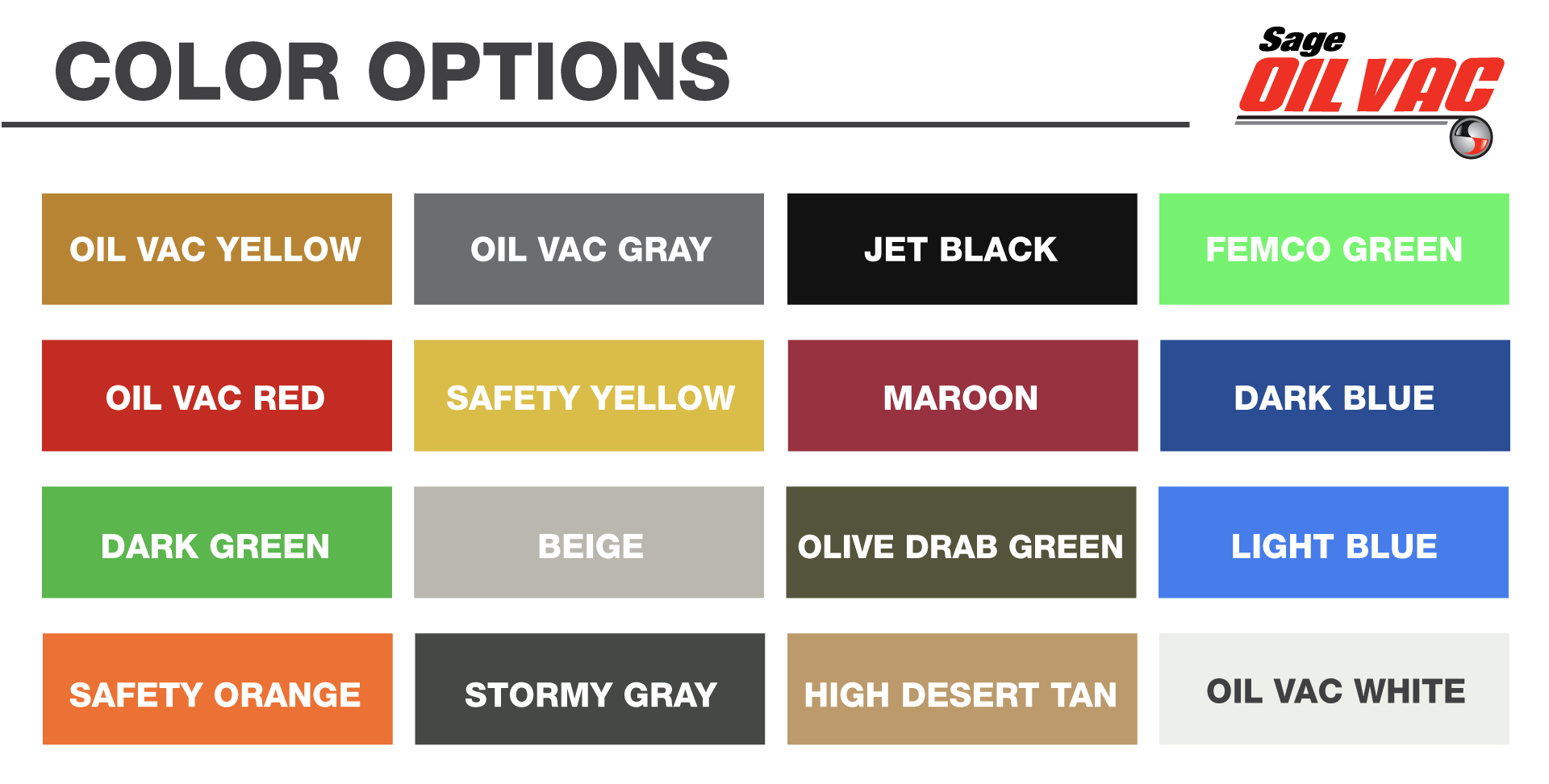

You asked and we listened. Sage Oil Vac is now prepared to bring your mobile lube equipment dreams full circle with our new custom color options. For years, the standard color for truck bodies has been oil vac white, and the standard colors for trailers, skids and carts have been oil vac yellow tanks with oil vac gray unit frames. But after seeing the increasing inquires for custom colors, Sage decided it was time to create more options. For an additional per unit upcharge, we now offer a select palette (see below) of new paint choices. Customers can also elect to provide their own color specifications outside of the color palette, but will be subject to an additional one-time color match fee.

Sage Oil Vac Paint Process

1.Verify paint selection with customer.

2.Pressure wash frames with a degreaser to remove mill oil and blast fabricated frames with Garnett, to prep to surface for paint.

3.Paint system using PPG Industrial Urethane DTM paint.

4.Touch up product as needed.

Please contact Sage Oil Vac for more specific paint information and custom pricing upcharges. View the color options here.

Every entrepreneur’s road to success is unique and one of a kind, Sage Oil Vac lives for the days when their equipment can help boost business. Eric Sanchez, owner and operator of EV Powerwash & Lube, LLC in Midland, Texas, says coming across Sage did just that.

Every entrepreneur’s road to success is unique and one of a kind, Sage Oil Vac lives for the days when their equipment can help boost business. Eric Sanchez, owner and operator of EV Powerwash & Lube, LLC in Midland, Texas, says coming across Sage did just that.

In 2013, Sanchez was a physical therapist by trade, but he just couldn’t pass up an opportunity to take advantage of the booming oil economy.

“I started with just a $400 powerwasher and a truck, and for a while I would just go around and wash oil transport vehicles,” Sanchez said. “Then in 2014, I started leasing an old gas station and I converted it into a lube shop where we did oil changes, safety inspections and powerwashes on just passenger vehicles.”

As his business clientele grew, Sanchez began to reach out to more commercial customers to see if they would be receptive to using him for their on-site personal maintenance (PM) needs.

“I started out doing personal maintenance for a couple customers that had transports and that is when I met Dwayne Green at Oil Patch Power and bought a Sage Oil Vac PM unit to continue doing that,” Sanchez said. “The big break was when I gained the business of ProPetro.”

ProPetro, a Midland, Texas-based oil field services company, provides hydraulic fracturing and other services to North American oil and gas companies.

“They let me start with their transport engine maintenance,” Sanchez recalled. “Once we built their confidence with that, they slowly started letting us work on their hydraulic pumps which require much larger engines with a lot more oil and filters. Now we’re doing maybe 60-70 percent of their equipment PM services.”

After Sanchez established ProPetro as a regular client, work requests from other companies started rolling in. This lead to a few more purchases from Green at Oil Patch Power and several new hires to his team.

“It’s been fast, it started as a leap of faith and it’s worked out,” Sanchez said. “I started with five employees and now I’m up to 30.”

EV Powerwash & Lube, LLC currently utilizes two Sage Oil Vac PM trailers and three lube skids. With the increasing jobsite no-spill regulations, Sanchez said the Sage equipment has really helped keep things clean.

“Everything we do has to be properly contained, properly vacuumed and disposed of, which is something we encounter with oil changes,” Sanchez explained. “Sage has made our job more efficient and more productive. It’s worked very well for us and the equipment is very well built. It’s definitely been a part of our success.”

Download and share this customer story.

We hear all about the hoops our customers jump through to appease their various jobsites, but there’s one restriction that has been gaining momentum in the last two years that has got our attention — no-spill jobsites. Yes, you read that right — construction contractors, building developers and fleet maintenance companies everywhere are turning to Sage Oil Vac because they need a solution to the signed agreements they have with customers stating the jobsite has a zero tolerance for any used oil spills.

“Two of our fleet maintenance customers who specialize in on-site oil changes have expressed that they could be potentially kicked off a site for even the slightest spill of used oil,” said Sage Oil Vac CEO, Aaron Sage. “As you can imagine, this can be very intimidating with class 8 trucks. These are engines that hold 12 gallons of oil each and they have to make sure they get the oil out of the truck without spilling a drop.”

Using Sage Oil Vac equipment systems in conjunction with Femco Drain Plugs allows the operator to connect directly to the engine sump or the engine component that is being drained. This eliminates the intermediate step of draining oil into an open container, not only removing the risk for spills, but cutting out an extra step entirely. Oil will be exchanged directly into the Sage use oil tank and ready for transport to proper disposal.

“With a jobsite close to water, it’s understandable to see that zero tolerance for spills,” Aaron said. “We have customers working with refineries in the Texas Gulf Coast successfully using the Sage and Femco combination. It’s all about working smarter, not harder.”

“It’s not your granddad’s jobsite anymore,” Aaron said. “As companies have become more environmentally conscious, spills will become less tolerable. It’s important to stay a step ahead of the game now and switch to equipment that can meet these needs.”

For more information about Sage Oil Vac equipment systems, contact Sage.

We can give away free Sage Oil Vac swag and talk up our amazing pump-free exchange systems until we’re blue in the face at the 2017 CONEXPO-CON/AGG show, but why just tell you about it when we can send you home with it? Yes, you read that right. We’re putting our equipment to the ultimate test — we’re giving away the use of a Sage lube skid for an entire year to one lucky winner.

“Our Sage Oil Vac lube skid line is what really sets us apart from competitors within the industry,” said CEO Aaron Sage. “It’s our flagship product and we’re market leaders in customizing skid packages.”

Right now, you’re probably saying something like: All right I’m in. How does the Sage Oil Vac Lube Skid Sweepstakes work? Easy. Just stop by Sage Oil Vac’s booth (S63129) at the 2017 CONEXPO-CON/AGG Show (March 7-11) or go to our online landing page: www.SageOilVac.com/CONEXPO2017 to read the official sweepstakes terms and conditions and submit your information to enter. The winner (who will be chosen at random) will then get to select the skid model they wish to use for a year.

“Anyone with heavy equipment that needs maintaining (so everyone) should enter this sweepstakes,” Aaron said. “If they win, they can pick their lube skid model and choose the unit that best fits their operation’s needs.”

With eight different models to choose from — Sage lube skids are often found in crane trucks, van bodies and mechanics’ trucks. Sage skids are great for servicing light towers, generators and trucking fleets with their smaller fluid capacities. These units are best suited to work vehicles with air compressors already mounted. Forklift pockets and mounting holes are standard in all skid models for easy transport. Our signature Sage Oil Vac pump-free design, creates a low maintenance skid with an estimated 10+ year product life.

“The best part of this product line is that it’s so versatile with all the different model sizes,” Aaron said. “The most popular model is a 2M46-3100 service skid which works well in the construction and ag industries as well as third party service companies who maintain fleets.”

With nothing to lose and everything to gain, Sage Oil Vac is encouraging everyone to enter online, even if they’re not attending the show.

“What we hear the most from our customers is that they love being able to end the day without having to change clothes — they usually end the day as clean as when they started,” Aaron said. “Couple that with faster fluid exchanges and low maintenance costs, and I think our product quality speaks for itself.”

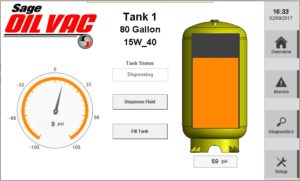

Sage Oil Vac, a market leader in professional lube equipment, is excited to announce the launch of its next ‘big’ product innovation — the NextLube monitor system. While it might not be large in size, the all-new NextLube monitor system will bring huge improvements in terms of productivity and ease of use.

NextLube will allow operators to integrate data while incorporating automation and fluid control with Sage Oil Vac mobile lube equipment. Based on customer feedback, Sage is developing this system to allow for more operator control with a touch screen centralized control panel to take out the manual actuation of valves.

NextLube will allow operators to integrate data while incorporating automation and fluid control with Sage Oil Vac mobile lube equipment. Based on customer feedback, Sage is developing this system to allow for more operator control with a touch screen centralized control panel to take out the manual actuation of valves.

“Based on customer feedback, we developed NextLube to allow more operator control,” said Sage Oil Vac CEO, Aaron Sage. “NextLube will act as a centralized control panel, so operators can have automated fluid dispense capabilities and monitoring within Sage Oil Vac mobile lube equipment.”

NextLube also streamlines maintenance operations by providing real-time fluid levels, totalized quantities of oil dispensed, flow rates and oil temperatures, all while having the capability to tie into existing customer telematics operations. It will also streamline maintenance operations by creating the ability to label individual tanks for quick recognition and organization. With more information to be given to the operator, this product will simplify the job by reducing the learning curve for new operators.

The intuitive touch screen panel will bring a straightforward presentation of information to every job as an optional add-on to Sage Oil Vac equipment. NextLube will display the gallons within the tanks, instead of the percentage, making the process easier for the technician to determine the amount of oil available to complete an exchange. More safety features and logic will be built into the system.

“The overall digitization of what has previously been a manual process creates additional possibilities in future updates,” Aaron said. “This could include running the system from an app on a smartphone or tablet, or incorporating back-end costs and telematics to specific equipment. The sky is the limit.”

NextLube system among top construction innovations

Each year, Construction Equipment magazine recognizes the industry’s most innovative new products — as well as companies’ commitment to research and development critical to bringing them to market — in its Top 100 New Products Award program.

Each year, Construction Equipment magazine recognizes the industry’s most innovative new products — as well as companies’ commitment to research and development critical to bringing them to market — in its Top 100 New Products Award program.

After a lengthy review of the myriad products new to the construction equipment sector in the last year, the 2018 list includes a big innovation from Sage Oil Vac, the NextLube monitor system.

“We considered several hundred product introductions in the process that led us to [the NextLube monitor system],” said Construction Equipment editorial director Rod Sutton. “Our editors made these selections independently, drawing upon our own experience with equipment technology and the equipment marketplace.”

That spirit of innovation and continued work to improve upon the NextLube system in the future was also a key component of the Construction Equipment Top 100 New products of 2018 Awards program.

“These awards serve to emphasize innovations, highlighting manufacturers who are investing in research and development. Their investments pay off for equipment users in the form of greater productivity, efficiency and safety,” Sutton said. “They also ensure a competitive marketplace.”

Contact your local Sage Oil Vac dealer for more information.

The entrepreneurial spirit is as important to Sage Oil Vac as it is to one of its most successful dealers, Cobalt Truck Equipment.

Just two years after Gary Sage founded Sage Oil Vac in 1993, Dan Duncan, President and owner of Cobalt Truck Equipment, opened shop in Idaho. Today, both companies are thriving and working together to bring the best products to customers within the construction, utility and heavy equipment industries.

“Cobalt’s introduction to Sage Oil Vac started with our interest and the needs of our customers for servicing wind equipment,” said Cobalt Vice President of Sales and Marketing, Paul Bedke. “Once the relationship developed, we discovered Sage met even more of our customers’ needs outside of wind power.”

Cobalt Truck Equipment works from four locations across the U.S. to provide customers with quality mechanics trucks, lube trucks, utility bodies, platforms, vans and more.

“Cobalt customers that use Sage products have been very pleased with the performance and efficiency of the Sage design,” Bedke said. “One customer in particular has converted all of their truck specifications to include the Sage waste oil system.”

Sage has provided on-site training to all four Cobalt locations (Nampa, Idaho; Spokane, Washington; Las Vegas, Nevada; and San Antonio, Texas). In addition, Sage sales representatives have participated in multiple trade shows and events with the Cobalt sales team.

“The lube trailers are some of the more popular items for our sales reps,” Bedke said. “The trailers provide diversity with our customers and their service trucks without the large investment of a dedicated lube truck.”

Cobalt currently offers the entire Sage Oil Vac product line.

“Sage is a good company with a long history in the vacuum-operated lube equipment business,” Bedke said. “They are very responsive to customer demands and do their best to provide a solution to meet those needs.”

Download and share this customer story.

To rent or to buy? It’s a question that plagues everyone in their lifetime, but for those in the wind turbine servicing industry options have always been limited. That is, until Sage Oil Vac began its Gear Oil Exchange (GOEX) Rental Program in 2009.

“Sage Oil Vac started the GOEX Rental Program based on the demand within the industry and from customer requests,” said Midwest Territory Manager, Chance Castillo. “Some companies needed to provide oil changes but didn’t necessarily want to make the full investment of purchasing.”

Sage currently rents out 1E6M-4 and 1E6K-3 models (with plans to add a 1D6G-2 to the fleet in spring 2017). Each model utilizes two tanks for Sage’s unique pump-free oil exchange system which allows the end-user to dispense and drain oil faster with vacuum technology. The 1E6M-4 has an additional two tanks for full flush and rinse capabilities, while the 1E6K-3 has one additional tank for limited rinsing capabilities or to carry a hydraulic fluid.

“How do our customers decide on renting versus buying? Well that all depends on the wind farm,” Castillo explained. “With our GEOX, the time between maintenance periods can be extended to anywhere from two to five years. It often makes more sense to rent a unit for a couple of months, perform the oil changes, and not have to think about it for a few years.”

Sage Oil Vac completes a thorough cleaning and checklist program between renters – new filters are installed and tanks are purged.

“Renters enjoy this program because it saves them from the initial capital investment and the hassle of maintaining the unit during the unused periods,” Castillo said. “The only thing they need to worry about is having a truck big enough to run the system. A ¾-ton truck is the minimum weight needed, but a 1-ton pickup is preferred as they can weigh up to 12,000 lbs during operation.”

GOEX systems in the program can be shipped anywhere within the continental U.S. on behalf of the customer or they can be picked up and dropped off at Sage Oil Vac headquarters in Amarillo, Texas. Training can be completed a few different ways — via a YouTube tutorial, if the unit is picked up in person in Amarillo, or a technician can travel to a wind location for an additional expense.

“I would conservatively say our rental units have performed as many as 3,000 gearbox rinse and flush operations on wind turbines across North America in the last six to seven years,” Castillo said.

Contact Sage Oil Vac for more GOEX Rental Program information and pricing!

Sage Oil Vac’s success comes from more than its quality equipment — it comes from a quality team of oil vac dealers, and our team just can’t stop growing. This year Sage added six new dealership partners to our roster of now 38 U.S. dealer locations and five international dealer locations.

Meet our newest oil vac dealers:

Hoekstra Truck Equipment (Grand Rapids, Michigan)

Hoekstra sells work-ready vehicles and accessories; they have several ties in the bus market in Michigan. We’re excited about working with them to create a few additional Sage products to change the oil in boats in a much cleaner and more efficient way. These guys are extremely motivated and we are happy to have such good representation in that area.

Truck Equipment Inc. (Des Moines, Iowa)

Truck Equipment sells and services products from a variety of manufacturers. We were introduced to the team in 2015 when they did some installation work with one of our LubeBuilders for a customer in Iowa. They have since agreed this year to represent our product line in Iowa. Every time we have visited they’re always excited to get on the road and show off our equipment.

Woodfield Canada (London, Ontario)

Woodfield Canada specializes in vehicle up-fit packages for commercial service and trade vehicles. We met the Woodfield team at the NTEA show in March 2016. They’re doing a great job of representing Sage in Ontario. They’re really picking up the product and running with it. With their knowledge and willingness to represent our brand, we hope to continue our momentum in the Canadian markets.

Intercon Truck Equipment, Inc. (Aston, Pennsylvania)

Intercon distributes and installs a full line of truck bodies, snow removal equipment, and related accessories. The Intercon team has been a bright spot for us — they have really been active with our product lines. There is a huge need for our equipment in the railroad and transit market and we know Intercon is going to be very successful in helping us communicate our solutions to that industry.

Southern Truck Equipment (Almont, Michigan)

Southern Truck specializes in rust-free truck parts and restorations. We also met their team at the NTEA show this year. They have worked extremely hard in promoting Sage Oil Vac equipment in the surrounding Detroit area — and they’re having some good success! These guys know their stuff when it comes to truck equipment and we’re happy to have them representing us.

Smyrna Truck & Cargo (Smyrna, Georgia)

Smyrna is a large and diverse truck equipment company that distributes several premier equipment brands. This team has been instrumental in getting our equipment out into the Atlanta area. We are getting tons of interest from Georgia and the surrounding states! It’s been great to have a Sage Oil Vac dealer in that area that can represent and educate customers about our product benefits.

Are you interested in representing Sage Oil Vac products? We’ll let you in on our top secret new dealer onboarding steps:

- We recruit, contact and introduce our company, products, and program over the phone and digitally.

- We then execute a face-to-face meeting.

- Next, we ship a demonstration model to your facility and change oil for you to demonstrate the Sage method. (This usually seals the deal.)

- Afterward, we’ll present our marketing program, dealer contract, and stocking requirements.

- Then you sign agreements and purchase a stock unit for demo purposes.

- Once everything arrives, we’ll travel back to your location to train your sales staff and conduct a few joint sales calls with your customers.

Want to hear more? Contact Sage Oil Vac!

We think Sage Oil Vac is a great company with efficient service trailers, but it’s always nice when someone else says it — especially when that “someone” represents a top of the line company like Nixon Power Services.

“Nixon Power currently uses six (Sage Oil Vac) oil change trailers to change the oil in customer-generator sets,” said Chuck Cameron, Nixon Power Services Vice President of Aftermarket Operations. “Sage Oil Vac is a great company with great equipment.”

All six Sage Oil Vac service trailers used by Nixon Power are the Preventative Maintenance 1C5H-3 model — one of Sage Oil Vac’s most popular models. Its tandem-axle design works well for off-road maintenance jobs.

About Nixon Power Services

Headquartered in Nashville, Tennessee, Nixon Power has boasted several solution-based offerings like design, installation and maintenance for power systems since 1914. Today, they reach customers in 13 states from five branch locations in the Southeast and Mid-Atlantic regions. Nixon Power discovered Sage Oil Vac products while they were visiting a fellow Kohler industrial generator distributor. After receiving their first Sage Oil Vac service trailer, they worked with the mobile lube equipment company to customize it to better meet their needs.

“We might use Sage trailers for a single job in a day or we schedule a week-long route where a tech travels to perform work at remote sites,” Cameron explained. “Before we ramped up to purchase a service trailer for each servicing branch, several locations would share one trailer.”

Service trailer features

The 1C5H-3 trailer features two fresh product tanks and one used oil tank, this service trailer works great for oil changes and antifreeze top offs. The open trailer design also optimizes load conditions, tongue weight, and axle weight for a safer transport to your job site.

Commitment to proper training

“We always want to make sure that our customers are comfortable running their new Sage Oil Vac equipment before we leave,” said Chance Castillo, Sage Oil Vac Midwest Territory Manager. “With Nixon Power’s staff of 70 technicians, this could have presented a bit of a training challenge. Luckily, they have a new-process trainer on staff, so we just needed to train him and he ensured everyone else received proper Sage equipment education.”

“Sage has been nothing but accommodating with the requests we have made,” Cameron said. “Training time has been minimal and (we like) the large tank capacities and the ease of use. We plan to purchase additional trailers as we continue to grow our services and also expand locations.”

To learn more about Nixon Power Services visit, www.nixonpower.com

Check out the lineup of Sage Oil Vac lube and service trailers.

Download and share this customer story.

When company founder Gary Sage decided to develop Sage Oil Vac into a full-time business venture, he knew he couldn’t do it alone. With the corporate office located in the heart of the Texas, it was simply impossible to reach every customer. Thus began the Sage Oil Vac dealer network, which now comprises of more than 30 dealers in seven countries.

Dwayne Green, President of Oil Patch Power in Greenville, Texas, has been a proud member of the SOV dealer network for two years.

“We are the No. 1 dealer for Sage Oil Vac in West Texas,” Green said. “I enjoy meeting new customers and educating them about the always-expanding Sage Oil Vac product line.”

Thanks to successful dealers like Green, Sage Oil Vac products are now being run in Australia, Brazil, Chile, Mexico, China, Russia, Wales, Kuwait, Iraq, South Africa, Turkey, Poland, Romania, Ukraine, France, Spain and several other European countries.

“The Sage Oil Vac products really help our customers save money, work safer and provide the best services out there,” Green explained. “Thanks to the Sage factory team, we’re able to provide a quick customer response as well as cutting-edge and custom built machinery with competitive pricing. We always put the customer’s needs first.”

Oil Patch Power started its company as an independent Sage Oil Vac dealer but has successfully expanded its dealership to include products from John Deere, Kubota, CK Gas, Kohler and more. Green attributes his success to discovering an important niche in the machinery market with his location in the Permian Basin (a large oil and natural gas producing area).

Green said his customers especially enjoy the way Sage Oil Vac products keep them clean on the job.

“I’ve had customers tell me, ‘I am as clean at the end of the day as when I started. I can get in my truck at the end of the day without changing my clothes.’”

Be sure to visit OilPatchPower.com for more information about Green’s additional products.