There’s no universal solution for businesses looking for a service van or mobile lube truck. That’s why Sage Oil Vac offers a complete line of service vehicles with customizable options. The right choice will help you streamline maintenance, optimize efficiency and boost lube technician satisfaction. So how do you decide which Sage Oil Vac solution meets the needs of your operation?

The answer requires balancing five key criteria:

- Driver availability

- Required payload capacity

- Ability to access jobsites

- Cost-efficiency

- Desired weather protection

We’ll walk through each factor to help narrow down what’s the best fit for what your operation is tackling.

How does technician availability influence service van or mobile lube truck choice?

Finding technicians with a CDL endorsement for Class 7 and 8 trucks can often be a challenge for some operations. Let’s face it, CDL drivers necessary to operate trucks over 26,000 pounds (11,793 kg) GVWR are in high demand and short supply. Sage Oil Vac has stepped to the plate by offering non-CDL trucks and service vans.

Non-CDL popularity continues to surge in response. Smaller Class 5/6 trucks and vans can be operated without a CDL, widening the available labor pool. In addition, crews not hauling fuel or diesel exhaust fluid (DEF) often find smaller vehicles a better fit. When comparing trucks vs. vans, non-CDL trucks tend to offer higher capacities and off-road capabilities than vans (more of that to follow). Conversely, while vans have smaller fluid capacities, they are more maneuverable in congested areas and urban environments where every inch matters.

“More contractors, dealers and rental companies are choosing non-CDL lube trucks due to the cost and efficiency benefits, where we’re seeing more interest in vans from fleet maintenance companies,” said Chance Castillo, chief sales and marketing officer for Sage Oil Vac.

However, for operations servicing sizable equipment fleets with large oil volume demands, there is no efficiency substitute for having a technician with a CDL. It’s important for operations to weigh available capacity against the time it would take to travel to and from the shop multiple times. Larger mobile lube trucks are unbeatable in terms of fluid volume.

How much payload and storage capacity do you need in a fuel and lube truck?

Whether a lube truck or van is a better fit will depend on the number and the size of machines in your fleet. Too small and you risk falling behind on your scheduled preventive maintenance (PM). Too large and you’re overinvesting in unused capacity.

“Finding the right fit is all about balance. You need to meet your needs today and consider any planned growth to ensure your investment will also meet future needs. This includes whether a lube van or a fuel and lube truck is the best option,” said Castillo.

Start by calculating how many machines you’ll service daily and reference OEM fluid change intervals and refill volumes. This will tell you how much fresh and used oil your vehicle needs to carry without having to make multiple trips back to the shop. Then determine if you need to carry additional fluids — such as fuel, coolant or DEF.

Payload is tied to the vehicle’s GVWR. This determines the number and the size of the product tanks. Sage Oil Vac offers lube (and fuel) solutions across a range of classes with several customizable options:

- Lube vans: Take on light-duty service work with capacity for up to 90 gallons (340.7 L) of new oil, 60 gallons (227.13 L) of used oil and 30 gallons (113.56 L) of coolant.

- Non-CDL lube trucks: Choose greater capacity with less restrictive licensing, including up to 420 gallons (1,589.87 L) of fresh oil, 220 gallons (832.79 L) of used oil, 60 gallons of new coolant (227.13 L) and 60 gallons (227.13 L) of used coolant.

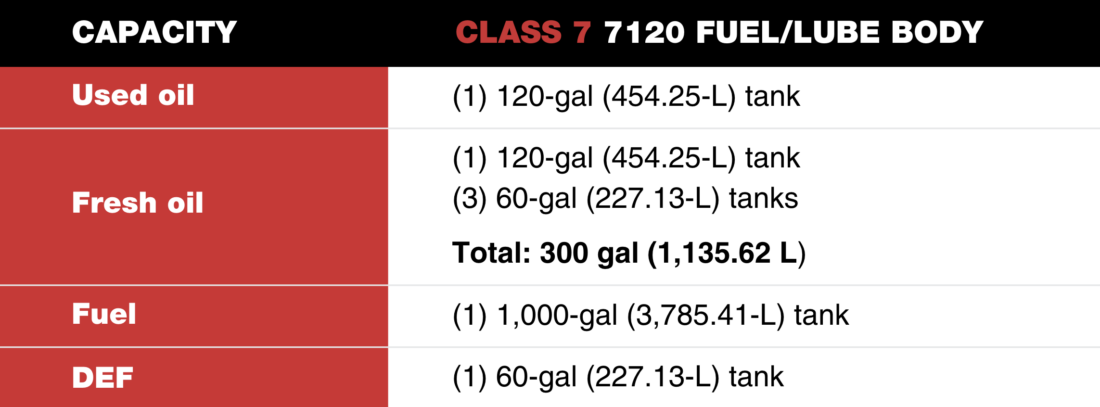

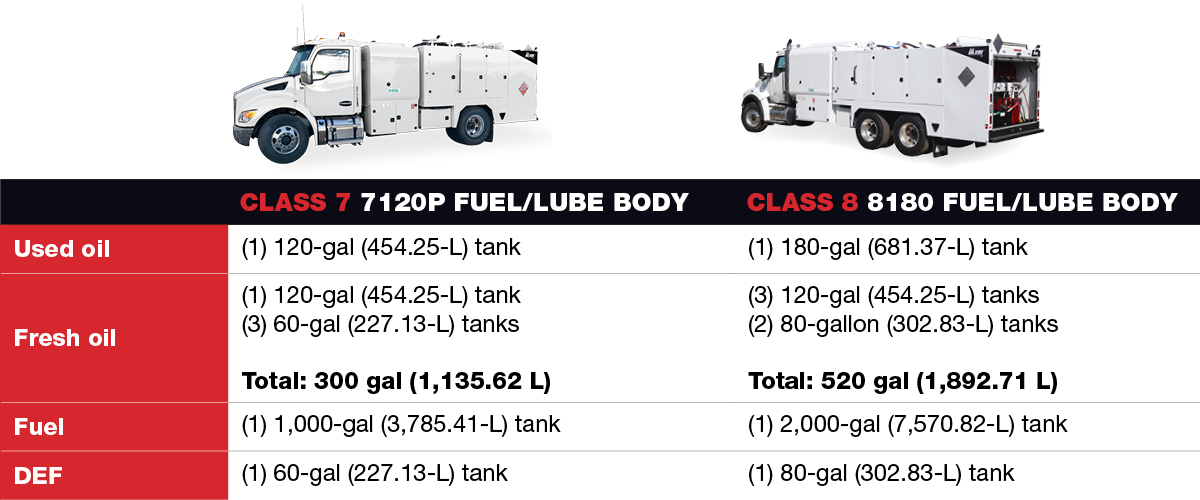

- Class 7 fuel and lube trucks: Carry 1,000 gallons (3,785.41 L) of diesel, 300 gallons (1,135.62 L) of new oil, 120 gallons (454.25 L) of used oil, 60 gallons of new coolant (227.13 L) and 60 gallons (227.13 L) of DEF.

- Class 8 fuel and lube trucks: Meet the most demanding fleet PM demands with up to 2,000 gallons (7,570.82 L) of diesel, 440 gallons (1,665.58 L) of new oil, 180 gallons (681.37 L) of used oil, 80 gallons of fresh coolant (302.83 L) and 80 gallons (302.83 L) of DEF.

Consider mobility and terrain access in your decision

Remember, payload is only part of the equation. Your PM solution must be able to get to the equipment. For tight, urban worksites or fleet yards, Sage Oil Vac mobile lube vans enhance maneuverability. They’re great for navigating narrow passages, low-clearance bridges and congested lots and parking garages. However, the mobile lube van may face limitations on rough terrain due to lower ground clearance and stress placed on the vehicle frames.

Non-CDL mobile lube trucks offer enhanced mobility while providing more ground clearance and robust frames to tackle demanding jobsites.

“Our non-CDL trucks are equipped with four-wheel drive to handle off-road conditions better than larger tandem-axle trucks. The single-axle design provides improved traction and agility on uneven terrain, often outperforming larger units in rugged environments,” said Castillo. “That said, customers with our service lube vans talk about the ease of those trickier urban environments and situations like generator maintenance in parking garages.”

If your technicians travel across variable terrain or between scattered sites, a smaller, nimble non-CDL truck may be your most productive choice. However, on jobsites with suitable access and ground conditions, larger lube trucks offer increased capacity to service larger fleets. Class 8 trucks have earned a reputation as the go-to solution on many large earth-moving and mining sites. If you need a more maneuverable alternative in these fluid-intensive applications, the Class 7 truck is a viable option.

Balancing lube vehicle cost and capacity

While carrying more fluids is often an advantage, bigger doesn’t always mean better — or more cost-effective. Smaller non-CDL lube trucks and vans often deliver better fuel economy and a lower total cost of ownership, especially when fluid demands can’t justify a Class 7 or 8 truck. In addition, vehicle size doesn’t mean you have to compromise on features.

Mobile service vans and non-CDL trucks are particularly cost-effective for light equipment fleets. Their smaller engines burn less fuel, and their initial investment is lower than larger truck platforms. If you don’t need high-volume capacity, these compact setups help reduce overhead while delivering on performance.

If you’re maintaining larger fleets, Class 7 trucks often strike a balance between capacity, maneuverability and fuel efficiency. This makes them a popular option for larger fleets.

For many larger fleets that service big machinery, there is no substitute for the Class 8 lube truck. The efficiency gained by having all the fluids available more than offsets the higher purchase and operating costs.

Protecting lube technicians from the elements

Technician comfort and productivity can take a hit in harsh weather or dusty environments. In cold climates, oil viscosity increases, slowing down fluid transfer and making open-air maintenance harder.

“Sage Oil Vac enclosed lube bodies, like our new non-CDL enclosed lube truck and service lube vans, help maintain oil flow and protect technicians from the elements, reducing fatigue and increasing efficiency,” explained Castillo.

Mobile lube vans provide enclosed, all-in-one-style workspaces where all fluid exchange components are accessible from the side door. This allows technicians to perform PMs without being exposed to extreme conditions. An enclosed service van or lube truck also provides an ideal space for branding with large, smooth side surfaces.

In applications where exposure to the elements is less of an issue, open lube trucks offer weight advantages and easier access to components.

Why Sage Oil Vac systems outperform expectations

Regardless of vehicle size or configuration, every Sage Oil Vac lube system uses exclusive pump-free vacuum technology. This system transfers fluids faster and cleaner than conventional methods — using compressed air to move fluids into and out of sealed tanks.

Here’s how Sage Oil Vac systems raise the bar:

- Faster fluid exchange:

- Fill fresh oil tanks at up to 15 GPM.

- Dispense products at 5 GPM.

- Vacuum hot oil at up to 8 GPM.

- Safer operations with sealed tanks that minimize fumes and prevent spills.

- Cleaner exchanges that reduce contamination of fresh fluids.

- More reliable performance with fewer moving parts, rounded tank corners and bottom-drain designs to prevent sludge buildup.

The best Sage Oil Vac lube vehicle for your operation depends on site conditions, technician availability, fleet size and budget. If the user needs serious capacity for demanding jobs, there are fuel and lube truck options. If CDL requirements are a concern, explore non-CDL mobile lube trucks and vans. Our product comparison tool and dedicated Sage Oil Vac sales team can help you find the perfect fit.

Preventive maintenance is a crucial part of your business. But it can feel like a hassle if you rely on third-party vendors to get it done (or you’re allocating skilled mechanic time to the job). If that sounds familiar, a dedicated lube technician could be the solution you’re looking for. Let’s explore three reasons construction companies are adding them to their teams.

1. They help you control your schedule and avoid downtime.

Hiring a third-party company to handle preventive maintenance seems convenient until you see service delays, inconsistent results, and coordination headaches. On the other hand, if you rely on your skilled team members to make time in their day for preventive maintenance tasks, they could fall behind on their more technical work.

Having a dedicated lube technician on your staff eliminates both problems. You’ll have more control over your schedule and the quality of the work. Work gets done when you need it — and to your standards.

2. They help you leverage skilled labor more effectively.

There’s no reason your diesel mechanics need to handle basic oil changes. A dedicated lube tech only needs simple training to do the job — and they’re a more economical option. Just look at the average hourly rates as of April 2025:

- Diesel mechanic: $281

- Service/lube technician: $171

A mechanic working on maintenance means you’re losing $11 an hour in efficiency. Shifting the work to a technician means you can increase billable hours and reduce burnout for your more skilled laborers. Plus, a dedicated tech can start to specialize in maintenance, learning OEM guidelines and increasing productivity.

Access your cost and benefits breakdown for adding a dedicated lube tech

Curious about the impact of a dedicated lube tech? Download our detailed cost-benefit breakdown to see how it can boost efficiency and reduce costs for your operation.

3. They help you build for growth and maximize ROI through efficiency

When it comes down to it, downtime is lost revenue. It’s that simple. A consistent schedule means you can plan around (or avoid) downtime related to preventive maintenance. It also helps your crews reduce the chances of wear-related equipment failures.

When you add a dedicated technician to the equation, you also create space for growth with no operational drag. That’s because your highly skilled crew members are focused on their work, not oil changes. The best part is that efficiency can compound. The more streamlined your workflow, the bigger your ROI can be.

Bonus tip: Maximize efficiency with a mobile lube system

Your future lube technician could be even more efficient if you set them up with a system engineered for on-site maintenance. Transporting equipment to and from a shop takes time, costs more and risks damage during the trip. Mobile lube systems eliminate all three issues, helping your technician focus on the job instead.

There are options for every budget and capacity need, including everything from small lube carts to lube trucks. Sage Oil Vac offers a full range of systems — without the hassle and extra maintenance related to traditional pump-based systems. Pump-free systems also faster, safer and cleaner, giving you even more advantages during preventive maintenance.

Here’s what we know

Hiring a dedicated mobile lube tech is about more than oil changes. It’s a strategic move for your business. Use it to:

- Boost uptime.

- Cut costs.

- Free up skilled labor.

- Reduce liability.

References

- ZipRecruiter. National average salaries as of April 2025.

In the trucking industry, every minute matters. Solutions made to reduce downtime are in high demand. That’s where mobile fleet maintenance comes in — and it’s been a game changer for companies like Wiers International Trucks.

Based in Plymouth, Indiana, the Wiers brand contains two companies that serve customers in Indiana, Ohio, Michigan, Kentucky, Illinois, Colorado and Texas. With a 60-year history, Wiers International Trucks, Inc. is one of the oldest International® truck dealers. Wiers Fleet Partners, Inc. is a trusted maintenance and repair source for light-duty, medium-duty and heavy-duty vehicles.

The family-owned brand’s experience with the time-sensitive trucking industry led them to an important insight: They could boost ROI with a mobile-first approach to fleet maintenance.

Wiers shifted its focus and started sending highly skilled, local technicians equipped with diagnostic technology to service customer fleets on-site.

“We’re in the process of growing our mobile fleet maintenance to take care of key customers,” said Wiers International General Manager Dave Finney.

The team uses a fleet of service trucks fitted with 18- and 20-foot boxes and two 14-foot custom-designed cargo trailers to bring mobile fleet maintenance to the customer. Sage Oil Vac lube skids are a critical part of the mix, turning the fleet into a mobile service powerhouse. The team now performs 80% of common mobile fleet maintenance and repairs with these trucks and trailers.

Expanding into mobile fleet maintenance

Before investing in a fleet, Wiers built a service trailer to test the initial mobile service concept. This trailer proved the concept was viable, but they needed experts to iron out the details and maximize efficiency. Industry recommendations pointed Finney and the Wiers team toward Sage Oil Vac in 2019.

Sage Oil Vac Sales Manager Chance Castillo helped identify a solution to maximize productivity and ROI — and he continues to help Wiers evaluate the brand’s evolving needs.

“We tend to be fairly demanding, and sometimes we’ll change what we are looking for during a project. Sage Oil Vac has always been up to that challenge. They pivot to find something that will meet the current needs. We’ve had a lot of bouncing ideas off each other,” said Finney.

For Sage Oil Vac, it’s all in a day’s work.

“I am passionate about helping companies like Wiers become more efficient when it comes to preventive maintenance and solve challenges for their customers that have unique demands,” said Sage Oil Vac Corporate Sales Manager Chance Castillo.

Building a customized solution

In 2021, Wiers built three units and set them up in trucks with larger 20-foot boxes. However, these longer trucks proved unwieldy moving around the yard. The company is now transitioning to 18-foot boxes.

The 20-foot boxes were previously built with 60-gallon Sage Oil Vac HS260V Heritage lube skids, but Wiers is transitioning to 30-gallon SS230V service skids to free up real estate in the smaller boxes. This allows room for toolboxes, a workbench and everything a technician needs to complete a service call.

The trucks are also outfitted with Sage Oil Vac accessories, including barrel straws, Filter Stingers™ and Used Filter Receptacles™ that simplify oil changes for the field service technicians and increase productivity.

Since Wiers plans to upfit an additional 15 trucks, the minimal effort required to install the lube skids is a major consideration. It is one of the two advantages noted by their team.

“One is the ease of installation. We’re actually building our own mobile service trucks. We were piecing together tanks, pumps and hoses. The skids greatly help with the build-out, making it more efficient and cleaner. Now, we use a forklift to set the Sage Oil Vac lube skids in the back of the truck, bolt them down and hook up the air. It’s a huge improvement in our upfitting process,” said Finney.

The other advantage relates to jobsite performance.

“It is easier for our technicians to use in the field. The employees using the service trucks with the Sage Oil Vac lube skids are more satisfied with the equipment. We really don’t get any complaints from our techs. And I think that that actually is a statement. The big “no” speaks louder than anything else. You know, techs aren’t one to compliment stuff, but there are no complaints. That is a great thing,” said Finney.

To learn how Sage Oil Vac lube skids can transform your trucks or trailers into mobile fleet maintenance solutions, contact the Sage Oil Vac team to get a quote.

The Sage Oil Vac legacy is built on the idea of improving operator experience. After all, Gary Sage invented a pump-free system to stop spills during oil changes. That innovation still drives our engineering team. And it’s why we’re introducing a newly enhanced Sage Oil Vac Class 7 truck.

Our newest enhancements are focused on improving the operator experience, including innovations engineered to increase durability, boost performance and improve jobsite safety.

The new Class 7 truck enhancements

The Class 7 trucks are built with heavy-duty fleets and equipment in mind, and the new enhancements make each job quicker and cleaner.

- New sealing systems for switch boxes and storage boxes hold up better against power washing and weather.

- The new multistage vacuum generator is up to 100% faster than the previous option, helping save time on the job.

- A tank fill indicator at the bulk-fill station eliminates guesswork while loading tanks.

- Wider backup camera views help increase jobsite safety.

- A relocated higher-capacity mechanics drawer and dedicated drain pan storage mean a more organized truck and less mess to clean up.

- An extended bumper creates a sturdier work area, while a safety ladder increases access to the truck bed.

- Optional features for the Class 7 fuel/lube body include safety cone storage, vise mounting on the truck bumper and backup sensors.

The newest features are available on both the PTO-driven hydraulic power model (7120P fuel/lube body) and a standalone diesel-driven model (7120S fuel/lube body).

A Sage Oil Vac promise

We’re proud of our lineup, but that doesn’t mean we’re afraid to make improvements. We’re driven to innovate and advance preventive maintenance technology for the industry — which means we’re always looking for ways to make our systems better. So, updating our heavy-duty service trucks was a no brainer.

We know purchasing a Class 7 truck is an investment. We owe it to our customers to continually invest in our products. Making every operator’s job safer and more efficient is our top priority, and we guarantee quality equipment and unbeatable customer service.

Heavy duty trucks ready for every jobsite

While not quite as large as our Class 8 service trucks, the Class 7 fuel/lube bodies are still a popular choice for crews that fuel and service large equipment. They also offer better maneuverability and fuel economy than the largest trucks in the lineup. Most often used for in-field operations, the Class 7 trucks have high-volume tanks for fresh oil, used oil and fuel.

“Our Class 7 trucks are a perfect fit for almost all medium- to large-scale operations needing quick and clean preventive maintenance,” said Aaron Sage. “And our new enhancements to these fuel/lube bodies make them the smart choice for anyone looking to upgrade or invest in better PM technology.”

Every Sage Oil Vac system is built with our exclusive pump-free technology to transfer maintenance fluids to and from equipment. This setup moves oil and other fluids faster than conventional pump-based systems, while the enclosed tank design prevents spills on the job.

Find the right truck with help from Sage Oil Vac

Still not sure if the enhanced Class 7 service trucks are the right fit for your operation? Our team is here to help. Get in touch to explore all your options or try our Product Match Tool to get a recommendation based on your work. All you have to do is answer a few multiple-choice questions.

Mobile maintenance is key for heavy equipment fleets. Because once heavy equipment makes it to the site, it stays there until the job’s done. The real challenge is finding the right preventive maintenance and fueling solution to keep all those machines running at peak performance.

Heavy-duty fleets call for high-volume fuel/lube equipment, which means you’re looking at a truck. If you’re fueling and servicing a large fleet (or even just a few pieces of mining equipment), you may need something with more capacity than a non-CDL option. That leaves either a Class 7 and Class 8 model as the best fit for your operational needs. But how do you know if a Class 8 service truck is right for your work?

What industries typically use Class 8 lube trucks?

Class 8 service trucks are used to maintain all kinds of equipment, but they’re more common in industries with large heavy equipment fleets.

“Our customers looking for Class 8 trucks typically work in mining or on large-scale construction projects like building highways or large commercial properties,” said Sage Oil Vac CEO Aaron Sage. “They’re maintaining and fueling a lot of big equipment, like haul trucks or earth-moving machines.”

When does a Class 8 truck make sense?

Both Class 7 trucks (straight trucks with a gross vehicle weight of 26,001 to 33,000 pounds [11,794 kg to 14,968 kg]) and Class 8 trucks (straight trucks with a gross vehicle weight of greater than 33,000 pounds [14,968 kg]) require CDL-certified drivers. If you’re considering a Class 7 truck, it’s worth checking out a larger model, too. It’s all about balancing your fueling and maintenance needs with your equipment investment. Here are a few scenarios where Class 8 service trucks make sense.

You need to maximize efficiency while maintaining a large heavy-equipment fleet.

Class 8 lube trucks have a significantly higher capacity than Class 7 trucks — which means you can finish more service visits without restocking fluids. Just look at the difference between the two models in the Sage Oil Vac lineup.

When you’ve got a large fleet of heavy equipment to fuel up, 1,000 gallons (3,785.41 L) can go fast. Same with 300 gallons (1,135.62 L) of fresh oil. If you’re consistently using that volume of fluids (or more), it could be worth doubling your fuel capacity with a Class 8 service truck. A bigger truck also means more storage space for everything technicians need on the job.

You need lube equipment that can handle elevation change and reach remote sites.

As you’ve heard now, Class 8 trucks are most commonly used to service equipment on commercial construction, highway construction, mining and quarry sites. And that’s not just because they have the fuel and lube capacities to maintain large equipment. Compared to Class 7 models, Class 8 lube trucks use engines with a higher displacement volume. As a result, they have the power to handle higher payloads — even while tackling elevation changes.

What other factors should you consider?

Class 8 lube trucks are a great fit for crews with busy maintenance schedules. Even so, you’ll want to weigh your options before you commit to a maintenance solution this size.

“Not every operation needs a Class 8 service truck,” said Sage. “But if you’re working with those high capacities of fuel and lube, it’s worth weighing your options.”

Compared to smaller trucks, Class 8 models have limited maneuverability. They’re larger vehicles, which can make them difficult to move around tight jobsites or urban environments. Their size — combined with their heavier payload and higher displacement engines — also impacts their fuel economy.

Finally, a Class 8 service truck is an investment. You should carefully consider your volume of maintenance work (both now and as your business grows) before you make your decision.

Why do crews choose a Sage Oil Vac Class 8 body?

Most Class 8 lube trucks use mechanical pumps to transfer fluid into and out of equipment. The Sage Oil Vac 8180 fuel/lube body is designed with exclusive pump-free technology, using compressed air to move fluids. That translates to faster, safer, cleaner and more reliable fluid exchanges.

- Faster: Compared to traditional pump-based systems, Sage Oil Vac equipment takes less time to vacuum-fill tanks and dispense products.

- Safer: Sealed tanks protect operators from fumes and the environment from spills. That’s increasingly important as jobsite requirements become stricter.

- Cleaner: Fewer contaminants can enter the system, thanks to sealed tanks.

- More reliable: Rounded tank corners that eliminate cracking. Fewer moving parts to minimize maintenance. Bottom-draining to prevent sludge. Sage Oil Vac systems are designed for minimal maintenance issues and a lower overall cost of ownership.

A variety of tank combinations are available, allowing crews to tailor their setup to their work. The body also includes individual control panels for ease of use in the reel cabinet, continuous LED fluid level monitors and a bulk-fill station for fast fill of oil.Find the right truck with help from Sage Oil VacYou don’t have to decide on the right maintenance solution alone. The Sage Oil Vac team is here to help. Get in touch to explore all your options. Not ready to chat yet? Try our Product Match Tool to get a recommendation based on your work. All you have to do is answer a few multiple-choice questions.

Increasingly popular pump-free mobile preventive maintenance systems driving development

Sage Oil Vac announced changes to the company’s sales team, bringing Steven Farr onboard as the territory business development manager and south central territory manager, and promoting Chance Castillo to chief sales and marketing officer. The strategic shift is designed to help the team better serve customers and meet an increase in demand for pump-free Sage Oil Vac preventive maintenance systems.

The changes will also support expanded distribution for the Amarillo Tanks lineup — which Sage Oil Vac purchased in 2021 to take control of its supply chain and ensure tanks were of the highest quality. Amarillo Tanks operates independently but the two companies work in tandem to take their industry capabilities to the next level, providing endless customization opportunities for customers.

“We’ve grown quite a bit over the last few years, and we don’t expect that to slow down,” said Sage Oil Vac CEO Aaron Sage. “Our team has put in the work to address increased demand and increased product portfolio. Adding Steven to the team and elevating Chance will set us up for success as we build up our team even further.”

Farr has more than 10 years of experience in the work truck industry. This includes his time with Knapheide, where he served as the Texas sales manager and designed sales strategies that helped increase annual regional sales by more than $12 million. He also developed training for the sales team, helping them connect with suppliers and enhance collaboration.

“I’m excited to have Steven on the team,” said Sage. “We have some incredible momentum going on, and I’m confident he’ll run with it.”

Chance Castillo, a long-time Sage Oil Vac team member, was promoted to chief sales and marketing officer alongside the addition of Farr. He started with the company in 2013 and learned the business from the ground up, leading in multiple areas to support continued growth. His encounters with Sage Oil Vac customers over the years have helped the company continue to refine its pump-free maintenance solutions. In his new position, Castillo will handle sales for the Sage Oil Vac and Amarillo Tanks brands, focusing on customer service and marketing.

“Very few people have had an impact on Sage Oil Vac the way Chance has,” said Sage. “He leads with humility and puts our customers first. There’s no better person for this job.”

The changes to the Sage Oil Vac sales team are designed to meet the increasing demand for pump-free maintenance equipment — while maintaining the company’s reputation for customer support. For more information on the Sage Oil Vac lineup of safer, faster and cleaner maintenance equipment, visit sageoilvac.com. For more information on the company’s lineup of steel tanks, visit amarillotanks.com.

From lube carts to Class 8 fuel and lube trucks, the Sage Oil Vac lineup offers mobile maintenance solutions for nearly every operation. But there’s always room for something new — especially when it helps customers get more done.

Meet the Sage Oil Vac LV230 and LV430 service lube vans. Combining benefits from models across the Sage Oil Vac lineup, these mobile service vans are tailored for maintenance work on tight jobsites and in urban environments.

Not familiar with this setup? We’re outlining four reasons service lube vans could be the right fit for your work.

1. They’re compact.

Think of service lube vans as a Goldilocks solution for certain maintenance crews. Not too big. Not too small. They’re great for navigating tighter jobsites, parking lots and fleet yards. They can also maneuver low-clearance bridges or tunnels, giving them an advantage in town over larger lube trucks. And they do it all with fluid capacities made for mobile maintenance for light-duty and construction equipment. Sage Oil Vac service lube vans can hold up to 90 gallons (340.68 L) of fresh oil, 60 gallons (227.13 L) of used oil and 30 gallons (113.56 L) of new coolant.

They’re also compact enough to avoid commercial driver’s license (CDL) requirements. CDL-certified drivers have been in demand for years, and that’s not expected to change. With non-CDL options like Sage Oil Vac service lube vans, companies don’t have to compete for commercial drivers. That means a wider potential labor pool.

2. They’re enclosed.

Covered storage is a definite plus for crews who work year-round. The enclosed setup helps keep oil viscosity low so it can flow even on colder days. It also offers valuable storage space on the job, especially when paired with smart organization options that keep everything in place. Sage Oil Vac service lube vans are equipped with Ranger Design™ shelving to maximize storage space and help operators keep track of parts and tools.

3. They’re convenient.

The best service vans are designed to make maintenance work simpler. For Sage Oil Vac service lube vans, that means having everything they need for fluid exchange accessible from the side door. Each tank has a separate control panel and continuous LED fluid level monitors, while a bulk fill station offers fast oil fills.

4. They’re economical.

Lube vans are a great fit for crews that don’t need huge capacities of oil or other fluids for their maintenance work. And because this solution is smaller than lube trucks, it is a more economical investment for companies looking to take light-duty vehicle and construction equipment maintenance on the road. The smaller size also means better fuel efficiency, offering additional savings.

The Sage Oil Vac advantage

Most mobile maintenance setups transfer fluid with mechanical pumps. The more mechanical parts in your equipment, the more maintenance and repair you can expect to perform.

Sage Oil Vac systems are engineered with exclusive pump-free technology, using compressed air to push oil into and out of tanks. This design translates to faster, safer, cleaner and more reliable fluid exchanges. Here’s how:

- Faster: A Sage Oil Vac system speeds up regular maintenance tasks, like:

- Vacuum-filling fresh oil tanks at up to 15 gallons (56.78 L) per minute.

- Dispensing products at up to 5 gallons (18.93 L) per minute.

- Vacuuming hot motor oil at up to 6 to 8 gallons (22.71 to 30.28 L) per minute.

- Safer: Sage Oil Vac systems have sealed tanks, protecting operators from fumes. The setup also protects the environment from spills, which is increasingly important as jobsite requirements become stricter.

- Cleaner: Sealed tanks and pump-free exchanges introduce fewer contaminants into fresh fluids — and help prevent spills.

- More reliable: Rounded tank corners eliminate cracking. Fewer moving parts. Bottom-draining to prevent sludge. Sage Oil Vac systems are designed for minimal maintenance issues and a lower overall cost of ownership.

Ready to find the maintenance setup for your work?

The Sage Oil Vac lineup has something for every maintenance crew, whether that’s a lube cart, service lube van or lube truck. Not sure which is the right fit? Contact the Sage Oil Vac team. We’ll help you find the right fit for your work.

There is no time to relax at Island Mobile Fleet Service. The company, based in Long Island, New York, thrives on providing timely customer-focused on-site preventive equipment and truck maintenance. The business performs oil changes on medium and heavy-duty trucks as well as heavy equipment from skid loaders to asphalt pavers and millers. The Sage Oil Vac LubeBuilder™ system is central to the company’s growing business.

Owner Nick Scavo had vast experience in preventive equipment and truck maintenance. He took what he learned while working with other companies and capitalized on an industry need in the area.

“While working for other companies, I would pour oil out of one bucket and collect waste oil in another bucket,” recalled Scavo.

Finding a better way

Scavo knew there was a better way. In 2017, he enlisted Sage Oil Vac to help develop a solution that took his efficiency to the next level. Together, Scavo and Sage Oil Vac worked to develop a customized LubeBuilder system for his ‘99 Chevrolet 3500 HD chassis that included a 30-gallon fresh oil tank and 30-gallon waste oil tank, both equipped with the Sage Oil Vac pump-free technology. The modularity of the à la carte LubeBuilder solution makes it easy to lay out and upfit a system for any vehicle.

“I never wanted to change oil the old-fashioned way when I started my business,” said Scavo. “I didn’t see that as profitable, so I started with Sage Oil Vac and never looked back. They were very helpful in guiding me to the proper equipment for my budget at the time of startup.”

Scavo is one of the customers over the past 30 years to realize reduced labor efforts, increased oil change speed and the ability to keep technicians and job sites clean by using the Sage Oil Vac system.

“Changing oil doesn’t need to be dirty, labor-intensive and time-consuming. The outdated practice of transporting oil in five-gallon buckets makes it nearly impossible to prevent spills. The Sage Oil Vac LubeBuilder system protects the jobsite from spills, keeps your technicians clean, and allows technicians to perform more oil changes per day through an exclusive pump-free fluid exchange system,” says Corporate Sales Manager Chance Castillo.

LubeBuilder customizes the tool to fit the task

As business grew, Scavo and Island Mobile Fleet Service upgraded to a Freightliner M2. The portability of the LubeBuilder system simplified the transition with the components being transferred to the new chassis.

When operations have specific PM needs, they’re often forced to make compromises in terms of tank capacities and mismatched fluid exchange components. In Scavo’s case, the Sage Oil Vac LubeBuilder system offered a completely customizable solution for his dedicated lube vehicle, helping cut costs by allowing him to select only the things he really wanted and needed in a PM setup.

That included lengthening the waste oil evacuation hose and fresh oil hose to reach the top of certain equipment without having to get the lube truck too close. The impact of his LubeBuilder system paid immediate dividends.

“I don’t have any employees because the Sage Oil Vac system enables me to single-handedly service all of my customers’ fleets with speed, cleanliness and efficiency,” said Scavo. “My largest-fleet manager customer doubted that I would be able to keep up with the demand by myself — until he saw my setup and witnessed it in action.”

Partnership builds confidence

Preventive equipment and truck maintenance is performed around the customer’s schedule. And with the right PM setup, trucks never have to be removed from service for an oil change, and no transport is required. Truck maintenance is completed on-site during the off-hours, including Sundays, if that is the only time the equipment is available for maintenance.

The majority of customers served are subcontractors for the local utility companies who have larger fleets, and Island Mobile Fleet Service will travel out of state when needed to serve its largest customers.

“I don’t second-guess going after larger fleets because Sage Oil Vac enables me to work circles around my competitors who still do it the old-fashioned way,” said Scavo. “I really don’t have any work-related stress.”

Attention to detail and a customer focus continue to drive growth. Scavo goes above and beyond traditional oil changes.

“I will do repairs on items I find need attention during a PM to minimize downtime for my customers,” says Scavo.

This customer focus continues to drive demand for mobile equipment and truck maintenance. Business is growing through customer referrals.

“I don’t advertise other than my truck being lettered up like a billboard,” said Scavo.

Looking forward, Island Mobile Fleet Service will continue to rely on Sage Oil Vac as a trusted partner.

“They have helped me grow my business to the point where I may have to set up another truck and hire help if I continue to take on any new work,” said Scavo.

Learn more about the Sage Oil Vac LubeBuilder™ system here.

Cold weather can bring oil changes to a crawl. As the temperatures plummet, oil viscosity increases, hampering fluid transfer and slowing the oil change process. This increases the difficulty for service technicians already fighting fatigue from working in freezing temperatures. An enclosed service truck helps solve the oil viscosity problem while also providing extra protection on dusty jobsites. However, a shortage of technicians with commercial driver’s licenses (CDLs) still poses a major hurdle.

Sage Oil Vac initially developed its first open non-CDL lube truck to expand customers’ labor pools. Eliminating the CDL requirement makes it much easier to find technicians. The open design of the initial truck saves valuable weight to maximize oil handling capability. Even so, there was a demand for lube trucks that could handle cold temperatures and dusty jobsites.

Sage Oil Vac got to work, leveraging the benefits of the original non-CDL design to build an enclosed service truck that addresses the need. Three onboard heaters allow fluids to retain low viscosity on the coldest days. One Miller CabEn™ heater and two Eberspächer diesel heaters work together to create an efficient solution for the harshest environments.

“We recognize the challenges service technicians face in cold climates. Our new non-CDL enclosed service truck builds on the benefits of a Class 5/6 truck by adding all-weather oil change performance,” says Aaron Sage, Sage Oil Vac CEO. “It continues the Sage Oil Vac legacy of designing solutions that improve conditions for the technicians while speeding up oil changes.”

Non-CDL lube truck benefits

Both open and enclosed non-CDL lube bodies provide an ideal solution for preventive maintenance on all types of equipment — from dozers and excavators to rental generators. They come with a lower upfront investment than Class 7/8 trucks, while smaller displacement engines offer additional savings on fuel.

With available space becoming a premium on many sites, maneuvering a large tandem-axle truck or trailer can prove challenging. These lighter-weight trucks offer enhanced maneuverability, often outperforming their larger tandem-axle counterparts in rough terrain. A non-CDL truck may be a good fit if you travel between jobsites with difficult landscapes.

Upfitting a non-CDL truck is hassle-free with Sage Oil Vac. You can easily transform an average Class 5/6 truck into a heavy-duty maintenance vehicle with a custom bed. And with both open and enclosed service truck options, you can select the best solution for your maintenance needs — whether you want to maximize payload or create all-weather capability.

The Sage Oil Vac non-CDL enclosed service truck builds on these advantages with:

- Six fresh fluid product tanks, including two 120-gal (454.25-L) fresh oil tanks, three 60-gal (227.13-L) fresh oil tanks and a 60-gal (227.13-L) fresh coolant tank.

- A 220-gal (832.79-L) used oil tank, a 60-gal (227.13-L) used coolant tank and a 120-lb (54.4-kg) grease drum.

- Three heaters, including one Miller CabEn™ heater and two Eberspächer diesel heaters.

- 60+ ft3 (1.7+ m3) of dry storage for tools and filters.

- Exclusive Sage Oil Vac pump-free technology powered by a Miller EnPak® A30 compressor and generator with a 19-hp (14.2-kW) Kubota diesel engine and a 15-gal (56.8-L) air tank.

The Sage lube truck advantage

Most mobile lube trucks use mechanical pumps to transfer fluids, which require regular maintenance and repair. Sage Oil Vac systems use compressed air to push oil out of the tank — no pump required.

Sage Oil Vac pump-free vacuum technology adds to the efficiency advantages of both open and enclosed service trucks. A Miller EnPak® A30 compressor and generator and a 15-gal (56.8-L) air tank power the exclusive Sage Oil Vac pump-free technology.

This low-maintenance fluid exchange system can vacuum fill products at up to 20 gallons per minute through the Sage Oil Vac barrel straw. Technicians can also vacuum hot motor oil from equipment at up to 6 to 8 gallons per minute with no moving parts to maximize efficiency.

Equipped for the job

From diesel generator maintenance to traditional fleet maintenance, a non-CDL lube truck body is economical and packaged for operator convenience. Sage Oil Vac non-CDL open and enclosed service trucks feature fluid control panels to make bulk fluid loading a cinch from ground level. Operators can easily view fluid levels with LED indicators and make changes with centrally located controls — available in the fluid reels cabinet, which provides generous dry storage space with tool/filter storage.

Sage Oil Vac non-CDL lube trucks come standard with:

- Barrel straws for rapidly loading bulk oil into the fresh oil tanks.

- Used Filter Receptacles™ (UFR) to secure and hold used oil filers as they drain, allowing crews to quickly vacuum up the used oil.

- A Filter Stinger™ designed to puncture used filters so operators can vacuum out oil before removing the filter from the machine.

Combine these features with the other benefits of an enclosed non-CDL lube truck — expanded labor pool, increased maneuverability and all-season performance —and crews get a powerful preventive maintenance tool.

Contact Sage Oil Vac to find out how a non-CDL lube truck could transform your preventive maintenance program.

The pressure to get more done with existing equipment has never been greater. With contractors often needing to push the limits of their existing fleets, downtime is not an option. In this environment, proactive preventive maintenance (PM) is essential for success.

Choosing the right mobile oil change equipment goes a long way toward achieving the desired outcome, keeping all PM of the fleet up to date. These days, there are a lot of great solutions on the market. Lube trucks are a great choice if you have enough PM work to maximize utilization and keep the dedicated truck working during the shift. Or, if you need both fuel and lube capabilities. Lube skids offer a flexible solution for servicing compact equipment and smaller fleets. Let’s not forget about lube trailers though. Lube trailers offer the capacity to keep up with larger fleets while also having the flexibility to optimize truck utilization with other tasks. So, who’s a good fit for a lube trailer? We’ll dig into this in more detail next.

Advantages of lube trailers

If your fleet requires more fluid capacity than lube skids can provide but you can’t justify a dedicated fuel and lube truck, lube trailers may prove the ideal solution. Lube trailers have larger tanks than skids and can carry more fluids (both fresh and used) while not requiring the use of a dedicated truck. Aside from what your PM needs are, determining the sweet spot for fluid capacity is typically determined by the tires, axles and capability of the truck used to pull it.

Budget is another important consideration when investing in any mobile oil change equipment and ensuring the equipment you choose maximizes ROI. With a lube trailer, the tow vehicle can be used to perform other tasks on the jobsite. Virtually any truck in your fleet with the appropriate GVWR can be used to move the trailer, including heavy-duty pickups and hitch-equipped heavy equipment. Plus, with a trailer, the truck’s bed space is still available.

“Lube trailers provide flexibility because you can simply unhitch them and use the truck for other tasks,” says Aaron Sage, CEO, Sage Oil Vac. “Also, if the tow vehicle breaks down, the trailer can be pulled by a different truck.”

For example, Houston-based Sprint Sand & Clay found running 200 pieces of equipment on multiple jobsites was more efficient with a dedicated lube truck. However, Texas-based Rabern Rentals didn’t have the same daily demands and was able to maximize efficiency with a lube trailer.

“With 500 gallons of fresh oil onboard [a Sage Oil Vac lube trailer], I can handle multiple services in a single trip and get rid of all the buckets I used to have to carry in the back of my truck,” said Tim Poland, service technician for Rabern Rentals.

Lube trailers also carry the advantage of being accessible. With larger dedicated lube trucks (Class 7 and above), service technicians must possess a commercial driver’s license (CDL) to operate. This limits the available labor pool in today’s competitive market. Sage Oil Vac offers solutions under the 26,000 GVWR threshold, in the form of non-CDL lube trucks, lube skids and a comprehensive lineup of lube trailers. These compact trailered systems can be pulled to and from the jobsite without a CDL with the right truck and trailer combination.

Why Sage Oil Vac lube trailers are more productive

Exclusive pump-free technology puts Sage Oil Vac lube trailers in a class of their own. Compared to traditional pump-based systems, our vacuum technology uses compressed air to move fluids into and out of tanks. A Sage Oil Vac system can vacuum fill fresh oil tanks at rates up to 15 gallons per minute, dispense products at up to 5 gallons a minute and vacuum hot motor oil at up to 8 gallons per minute. The result? More machines are serviced daily than possible with pump-driven models. No pumps mean less long-term maintenance and increased reliability.

The Sage Oil Vac pump-free process also uses sealed, non-vented tanks, which means contaminants stay out of the tanks and result in cleaner and safer oil changes.

Sage Oil Vac lube trailers come in both open and enclosed configurations and can be equipped with different tank sizes to accommodate the capacity needed. From our 380 PM trailer that offers 140 gallons of fluid capacity, to the 6220 jobsite trailer that packs a punch with a tandem-axle 13,000-pound gross vehicle weight rating (GVWR) trailer with 920 gallons of fluid capacity, we offer trailers equipped to meet the demands of your operation. Plus, a wide variety of configurations, accessories and available storage space sets service technicians up for success.

If you need more capacity than a lube skid and a flexible option that maximizes truck utilization, a lube trailer may be the ideal solution. Contact a Sage Oil Vac dealer to discuss how a lube trailer can increase PM flexibility — or explore our available inventory to see lube trailers available to ship right now.